By Dan Watson

I have spent the past several issues of Tow Professional explaining oils and how they lubricate. Understanding the fundamentals of lubrication and selecting the proper lubricant is certainly the primary responsibility of the maintenance personnel. Once that choice is made, it is now necessary to insure the oil is as clean as possible to function to the highest level to provide protection for the operating equipment.

First, let’s take a look at how engine oil gets contaminated and understand exactly what we are trying to filter out of the oil as it is in use.

Abrasives

Dust and Dirt

The quality and design limitations, especially the proper fit and seal of air cleaners and crankcase ventilation systems, allow a certain level of dust and dirt into the engine. Intake systems, including the structure supporting the air filter and the turbo charger, can permit unfiltered air to enter the engine. Proper maintenance of the engine and its accessories can minimize the amount of contaminants entering the lubrication system.

Metal Particles

Normal wear of engine parts produces very small metal particles that are picked up and circulated by the oil. Particles of road dust and dirt increase wear rates and generate larger, even more abrasive metal particles that are circulated through the engine by the oil. While oil filters help keep these particles at a minimum, they can’t remove them entirely.

Combustion By-Products

Soot and Carbon

Incomplete combustion produces soot, carbon and other deposit-forming materials. An engine running too “rich,” or with too much fuel, increases contaminant levels.

Soot is a natural product of diesels engines; ultra-low sulfur diesel coupled with improved turbo control of intake-air has reduced the level of carbon soot produced by modern diesel engines. Unfortunately, the requirement for exhaust gas recirculation (EGR) creates a high soot load for the diesel engine oil. Light-load, low-speed gasoline engine operation and high-load, low-speed diesel engine operation increase levels of these combustion by-products.

Realizing that it is impossible to avoid the engine oil becoming contaminated, it is obvious that finding effective filtration mechanisms is critical to achieving desired engine life. There are two methods of filtering engine oil: Full Flow filtration and Bypass (Side Stream or Parallel) filtration.

Full Flow Filtration

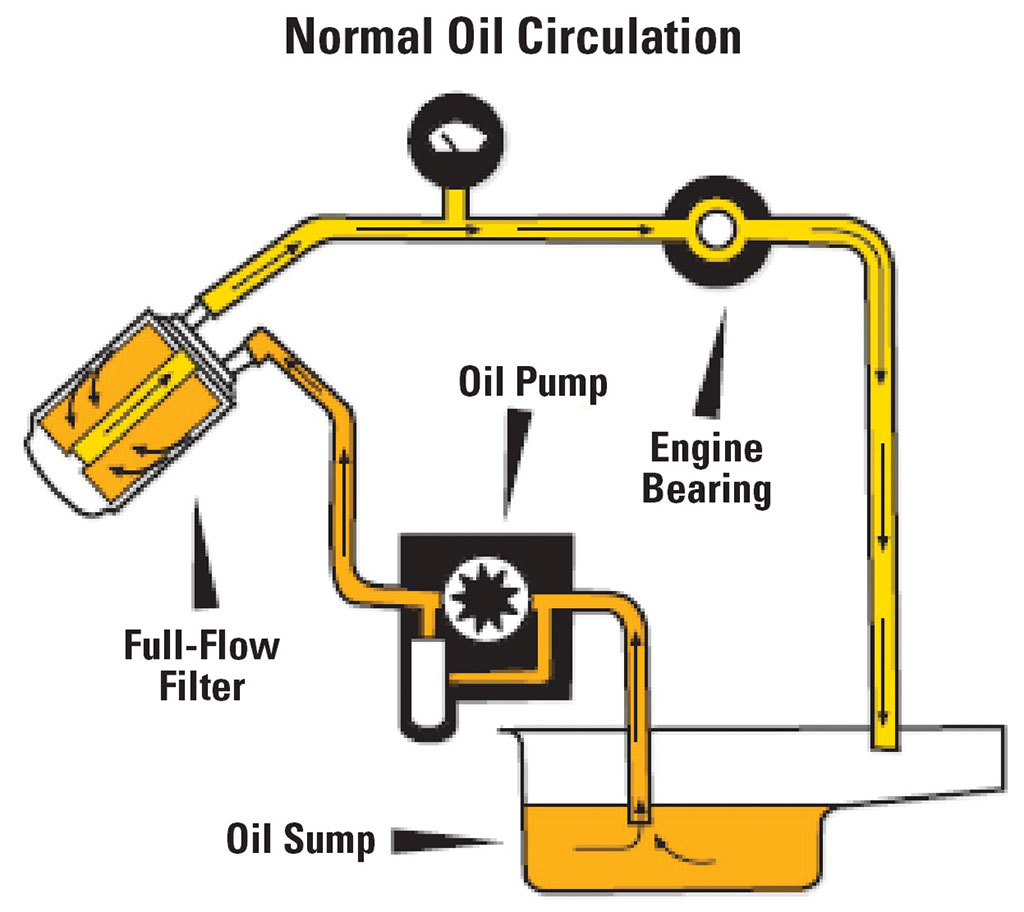

Full-flow oil filters install directly into the line of oil circulation; the oil passes through the filter as it travels between the oil pump and the engine (see Figure 1). A full-flow oil filter must remove and hold contaminants without obstructing oil flow to the engine.

Because they use a thin layer of porous filter paper, most oil filters on the market compromise the filtration of finer materials. Such filters have almost no extended cleaning ability because they have a low capacity for storing dirt.

These “surface-type” paper filters quickly become restricted as debris builds up on the paper surface, forcing the filter by-pass valve to open and allow unfiltered oil into the engine.

By-Pass Oil Filtration

Because oil must be filtered quickly while removing most of the particles, the average full-flow filter can only trap particles as small as 20 microns. By-pass oil filtration uses a secondary filter (see Figure 2), with the purpose of eliminating nearly all contaminants in engine oil. By-pass filters have high capacities and eliminate much smaller particles than full-flow filters, including those in the 2 to 20 micron range, soot and sludge.

* Courtesies of Amsoil Inc.

Oil Circulation using an AMSOIL Spin-On By-Pass Filter

By-pass filters operate by filtering oil on a “partial-flow” basis. They draw approximately 10 percent of the oil pump’s capacity at any one time and trap the extremely small, wear-causing contaminants that full-flow filters can’t remove. The continual process eventually makes all the oil analytically clean, reducing long-term wear and helping extend oil life.

Filter Ratings

Filter media is the heart and soul of the oil filter; regardless of how you construct the filter, if the media is inefficient at removing contaminates the filter is junk. No matter how much I dress up a Donkey, I can’t make that Donkey a Thorough Bred race horse. With filter media, performance is all that matters; you get what you pay for.

Filtration is measured in percent efficiency at removing particles of certain sizes. For example, a filter may be rated as nominal at 40 microns; this means the filter removes a nominated amount of contaminate, by weight for the rating. Inconsistent methods of determining a nominal rating has resulted in nominal as being virtually useless as a rating. Absolute rating, on the other hand, is very accurate and useful in rating filters. Absolute is defined as: the cut-off point, which refers to the diameter of the largest spherical glass particle, normally expressed in micrometers (mm), which will pass through the filter under laboratory conditions. In simpler terms, no particle larger than the absolute micron rating should get through the filter. In the real world, this is not completely true, so a system of establishing filter efficiency has been established.

* Courtesies of Amsoil Inc.

Establishing a Beta ratio is done by dividing the number of particles of a particular size in the upstream flow by the number of particles of the same size in the downstream flow:

where bx is the beta ratio for contaminant larger than x mm (microns)

Nu is the number of particles larger than x mm (microns) per unit of volume upstream

Nd is the number of particles larger than x mm (microns) per unit of volume downstream.

The beta ratio is an indicator of how well a filter controls particulate; i.e., if one out of every two particles (>x microns) in the fluid pass through the filter, the beta ratio at x microns is 2; if one out of every 200 of the particles (>x microns) pass through the filter the beta ratio is 200.

Therefore, filters with a higher beta ratio retain more particles and have higher efficiency.

Efficiency for a given particle size (Ex) can be derived directly from the beta ratio by the following equation:

The following table lists some selected beta ratios and the correspondent efficiency:

|

b value to x microns |

Cumulate efficiency % |

||||||||||

|

bx |

for particles x micron |

||||||||||

|

|

Capacity

Filters have to store contaminates removed, and this is referred to as capacity. It is not easy to find an actual capacity rating, but you can determine how many miles the filter can be used before it must be changed. The longer the filter is allowed to be used represents how much debris the manufacturer has designed the filter to store.

Flow Rate

Measured in gallons per minute (GPM) is determined by the engine manufacturer for proper lubrication of the engine. Most full flow oil filters must pass a minimum of 9 gpm, some larger diesels require more flow, so rely on your owner’s manual to specify only filters that meet the flow rate.

To select filters for your equipment, you should research the filter ratings on various filters. It may be hard to find the information you are looking for on the filter packaging. You should be able to research online at the manufacturer’s website and find the filter ratings. Look for ratings in absolute not nominal, and, in some cases, you may find beta ratings. Beta ratings are not likely to be found for auto and truck filters; they usually are there for hydraulic and industrial filters. Synthetic filter media is superior to cellulose and much less susceptible to streaming and medial failure. A superior filter will have an absolute efficiency of greater than 98% for 20 micron particles and a mileage rating greater than the recommended oil change interval.

Never change your oil without changing your oil filter. Dirty oil is abrasive and will shorten the life of your engine.

In the next issue, I will discuss the advantages of bypass filtration and explain why it is so necessary for modern diesel engines.

If you come to the Florida Tow Show in April, stop by the Amsoil booth and say hello.

www.thelubepage.com

(407) 657-5969