By Bob Ernst, J. J. Keller & Associates, Inc.

If you look around any workplace, you are likely to see lots of different chemicals being used. With almost every chemical, there are risks to you, your physical surrounding and the environment as a whole. The possibility of accidents and injuries is always present when you’re working with hazardous chemicals, no matter how harmless they may seem.

The Occupational Health and Safety Administration (OSHA) says that workers have both a right and a need to know information about the hazards of the chemicals they work with or are exposed to, especially so that they can take steps to protect themselves when necessary.

On March 26, 2012, OSHA published the revised Hazard Communication Standard (HCS) “harmonizing” it with portions of the Globally Harmonized System (GHS). The GHS is an international approach to hazard communication that provides universal criteria for identification and communication of chemical hazards.

The revised HCS changes the existing requirements for classifying chemical hazards, the format and content of Safety Data Sheets (SDSs), and the labeling of chemical containers.

OSHA has established “phase-in dates” for compliance with the revised standard, which will be fully implemented by June 1, 2016. During the phase-in period, OSHA says that employers can comply with the old standard, the revised standard, or both.

Written plan

The HazCom standard has always required that employers prepare and implement a written hazard communication program. The written program is intended to ensure that the employer is in compliance with the all of the required elements of the standard.

The written program must also include a chemical inventory, which is a list of the chemical hazards known to be present in the work environment.

Container labels

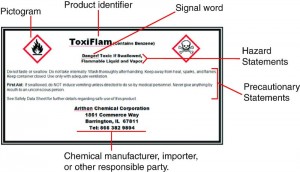

One of the most visible changes we will see is new container labels. The label is a snapshot of the hazards and protective information related to the chemical, and a summary of the more detailed information available on the SDS.

All hazardous chemicals shipped after June 1, 2015, must be labeled, tagged, or marked with six specified label elements, four of which have been “harmonized” within the GHS system, and are pre-determined based upon the chemical’s hazard class and category.

Those required label elements are:

- Product identifier;

- Signal word;

- Hazard statement(s);

- Pictogram(s);

- Precautionary statement(s); and

- The name, address, and telephone number of the chemical manufacturer, importer, or other responsible party.

Pictograms

Although the GHS system uses nine pictograms, OSHA has designated eight pictograms under the HCS for application to a hazard category.

OSHA requires pictograms on shipped containers be in the shape of a square set at a point and include a black hazard symbol on a white background with a red frame sufficiently wide enough to be clearly visible.

Workplace labels

Any container of hazardous chemicals in the workplace must at a minimum include the product identifier and general information concerning the hazards of the chemical. This would apply to any containers of hazardous chemicals drivers carry on their trucks.

For instance, if your tow trucks carry small amounts of gasoline, so-called “non-bulk packagings,” the container must be DOT approved and must be marked with the name of the contents and with an indication of the hazards of the material it contains.

For those containers that are received already labeled from the supplier, and are used in the workplace, simply maintaining the label that is on the container from the supplier is the best and easiest option.

Some employers use third-party workplace label systems, such as those that have numerical ratings to indicate the hazards (e.g., National Fire Protection Association (NFPA) or Hazardous Materials Identification System (HMIS)).

OSHA says that employers may continue to use third-party label systems, as long as workers have access to the complete hazard information found on the SDS.

Consumer products

You will not see a change to the labels on containers of “consumer products,” which are those chemicals that anyone can purchase over the counter.

Safety data sheets

The SDS is the source of detailed hazard information about the hazardous chemical being used. The revised HCS requires that the information on the SDS is presented using a consistent 16-section format in a specified sequence:

Section 1. Identification

Section 2. Hazard(s) identification

Section 3. Composition/information on ingredients

Section 4. First-aid measures

Section 5. Fire-fighting measures

Section 6. Accidental release measures

Section 7. Handling and storage

Section 8. Exposure controls/personal protection

Section 9. Physical and chemical properties

Section 10. Stability and reactivity

Section 11. Toxicological information

Section 12. Ecological information

Section 13. Disposal considerations

Section 14. Transport information

Section 15. Regulatory information

Section 16. Other information, including date of preparation or last revision

The SDS must contain Sections 12 through 15 to be consistent with the GHS, but OSHA will not enforce the content of these sections because OSHA has no authority over those areas.

Safety data sheets must be available for each hazardous chemical in the workplace, and must be readily accessible to employees when they are in their work areas. For drivers, the SDSs may be kept at the primary workplace.

Training requirements

Employees who may be exposed to hazardous chemicals must be provided with information and “effective” training at the beginning of each new assignment involving a hazardous chemical or whenever a new physical or health hazard is first introduced. Effective training means that the training be understood by the employee, so training may need to be provided in a language other than English.

Employers are required to inform employees of the basic requirements of the standard, such as specific chemical hazards in the employee’s work area, the location of the written HazCom program and SDSs, and how to read container labels and SDSs.

Hazardous chemical training must include:

- How to detect the presence or release of hazardous chemicals;

- The physical and health hazards of those chemicals; and

- Precautions employees can take to protect themselves against hazards, such as safe work practices, personal protective equipment, and emergency procedures.

Your HazCom Program

OSHA says that employers can implement an effective hazard communication program

by following these six steps:

Step 1. Learn the standard/Identify responsible staff

Step 2. Prepare and implement a written Hazard Communication Program

Step 3. Ensure containers are labeled

Step 4. Maintain Safety Data Sheets (SDSs)

Step 5. Inform and train employees

Step 6. Evaluate and reassess your program

OSHA believes that the Hazard Communication Standard will ensuring that hazardous chemicals in the workplace are identified, and that proper measures are implemented for safe use and handling. By understanding the hazards of the chemicals, and using available information to pick the proper control measures to address these hazards, we can achieve safer workplaces.

Copyright 2014 J. J. Keller &

Associates, Inc.®

PO Box 368, 3003 Breezewood Lane

Neenah WI 54957-0368