The history of The Will-Burt Company, today, known at the world’s leading producer of mobile elevation products, can be traced back to 1894. It all began when two brothers, Burton, and John Cope, sought a better way to make a living by opening a general repair shop for farm machinery. By 1900, the business had grown by adding the Cyclone Drilling machine (water and oil drilling rig) to their offerings along with a new partner in William Tschantz. It was this year that the business moved to Orrville, Ohio, a bustling railroad town in the farming heartland, where the business remains today.

Will-Burt went through many changes in the first two decades of the 1900s. John Cope passed away leaving Will and Burt (yes, that is where the name came from, but it did not happen until 1915) to manage the business. The entrepreneurs were prolific inventors. Burt patented a device that moved car chassis from train box cars to auto dealerships for final assembly (in the days before the assembly line). Will earned several patents related to mechanical farm machines and later in life he developed patented meat grinders for use in grocery stores – some of these designs are still used today! Unbelievably, the meat grinders came full circle and Will-Burt’s manufacturing services division makes parts that are used in these meat grinders for the company that holds these patents. One other interesting product that was launched in the era was a carpenter’s vise, later marketed as the Versa-Vise. This was a unique vise that allowed a user to mount it at different angles for any job. Will-Burt manufactured this into the 1980s then sold it to a former employee that still offers them for sale today. Collectors seek the original models.

The Will-Burt Company was incorporated in 1918. Will Tschantz had departed and Ed Baer, Burt Cope’s nephew had joined the business. In 1920, Burt Cope cut a deal with a company in Pittsburgh to make automatic combustion regulating equipment used in coal burning power plants and on steam ships as a contract manufacturer. Will-Burt went from a company of less than twenty people to over two hundred in a brand-new factory on Main Street in just a year. Even though the country was struggling through the Great Depression, Will-Burt expanded into making coal stokers that were used in businesses and homes – you might remember seeing one of these noisy and scary contraptions in your grandparent’s basement, especially if you grew up near coal country. The product line was expanded into furnaces and even water heaters. As natural gas and fuel oil replaced coal for heating in homes, sales of these products shrank to the point where the company closed the line down in 1995.

Going back to the middle of the 20th century, Will-Burt like so many other companies in the USA, supplied products and components for the WWII war effort. The top-quality metal working and painting skills and equipment that Will-Burt possessed earned the company the prestigious Army / Navy “E-Award” for production excellence.

Shortly after the conclusion of the war, Burt Cope passed away. Ed Baer was now CEO. Along with his son Bill Baer, they continued to look for new opportunities to expand the business. The post WWII housing boom helped drive coal stoker sales. Consumerism was taking off and Will-Burt created several products to tap into this. In 1949, Will-Burt’s Little Farmer cultivator was released. A clever walk behind tiller type product that was designed to accept many different implements such as a plow, blade, and even a seed planter. The carpenter’s vise was reworked and branded the Versa-Vise in the 1950s and was sold via mail order and through hardware stores for $12.95 ($140 in today’s dollars).

Will-Burt looked to expand its contract manufacturing business that continued to focus on metalworking in the 1960s. Will-Burt produced parts and components for AMF Bowling, Flo-Tork and many local businesses. We continue to produce parts and assemblies to this day for the construction equipment and defense sectors.

A decision was made in 1970 to acquire a small local business for its production machinery. This decision would change the future course of Will-Burt (even though no one realized it at the time). The tool and die shop that was acquired also made pneumatic telescopic masts that could elevate radio antennas and lights. Sales of the telescopic masts were minimal throughout the seventies and the business was a drag on profits, but technology was changing rapidly and would lead Will-Burt in a new direction.

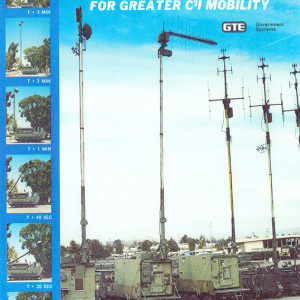

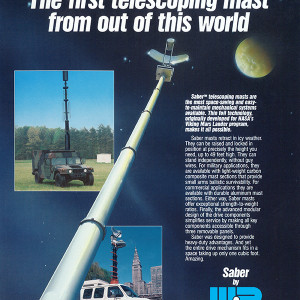

The 1980s was the most turbulent decade in Will-Burt’s history. The decade starts off with Will-Burt winning a contract to supply a telescopic pneumatic mast for the US Army PATRIOT program. The masts elevate radar and communications equipment for the missile defense system. The PATRIOT system has gone through several updates over the years, but Will-Burt still provides the masts for the system. It was during this time that the commercial need for a 42-foot telescopic mast for use in the burgeoning live broadcast news industry developed. Will-Burt had just the system in the ultra-reliable and now iconic 7-42 non-locking pneumatic mast. This mast was used by nearly every news van in the US to elevate a microwave dish that would transmit a live video feed back to the news station. Most news stations have now transitioned to cellular video transmission technology, so the Will-Burt 7-42 mast is no longer needed in the live news field – but it was a great 35-year run!

1985 was the year the good times came to a screeching halt. Bill Baer, who had been CEO for more than 20 years and had worked for the company since 1936 died unexpectedly. Mr. Baer was the last Cope family member to run the company. Also at this time, the company was defending itself against a frivolous lawsuit that drained resources and caused the Board to resign. Bankruptcy looked imminent; however, the new president who had been with the company for 10 years had a plan to save the company. All outstanding shares were purchased by the company by mortgaging everything available and ownership was turned over to the employees as an ESOP. The next few years were difficult – changes had to be made, modern equipment needed to be purchased to compete and employees were retrained to succeed. By 1990 a new culture of employee ownership and continuous education had taken root that is flourishing today.

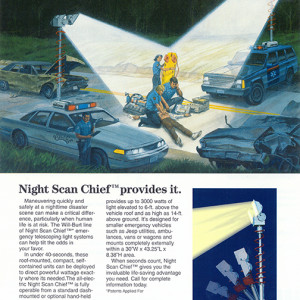

The 1990s is when modern Will-Burt starts to take shape. The newly trained and empowered employee-owners start to look for ways to expand the business. It is time to cut loose products from the past that no longer add value such as the coal stoker line. New products are developed such as mobile light towers and more powerful pneumatic masts. Money is invested in sales and marketing and light towers become Night Scan and military masts become Saber then Stiletto. The welding, machining, metalworking, and painting skills of the workforce are used to make GSA registered file cabinets and storage containers for the US government and their contractors. Will-Burt achieves ISO 9001 certification for its Quality Management System. By the end of the decade, Will-Burt starts to focus on exporting products into European and Asian markets.

The dawn of the new millennium saw Will-Burt expand even further under a new CEO. New elevation product lines are added by an expanded engineering department, plant expansions with the doubling of Orrville’s footprint, and continued investments in modern machines and employee training. To help accelerate the growth of the company, acquisitions are made to expand the company’s reach and product offerings.

A company was purchased in Tulsa, Oklahoma that added telescopic lattice towers and elevation trailer integration capabilities to the portfolio. A company was purchased in Waischenfeld, Germany, GEROH, that added cable driven masts, perfect for harsh environments, and spindle driven telescopic masts that are the most precise in the world – exactly what you would expect from a German company. This acquisition gave Will-Burt an excellent launching point for further expansion in Europe. Later, a company that makes pan and tilt positioners, often used on top of masts to move antennas, was purchased in the UK. All the while, sales were expanding in Asia and the Middle East.

Will-Burt’s rich heritage of manufacturing quality products, re-invention, and investment in our employees has led us to where we are today, a company of three hundred employee-owners that are guided by our 7th CEO, Richard Lewin, whose strategic vision focuses on integration, intercompany and internationalism. Will-Burt operates as one company that’s vision is to Elevate Innovation and we look forward to our next one hundred years.