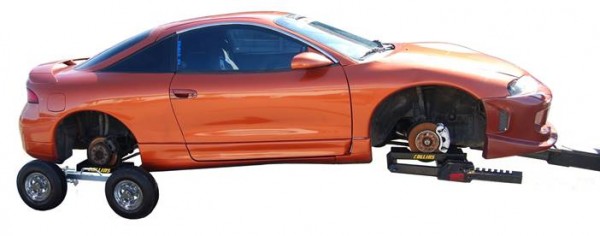

135 miles – 35 of those through rough dirt roads, 100 highway miles. That is the recent log of a professional tower, one of many throughout the week that come in from motorists being stranded or local businesses servicing vehicles. Each one an opportunity to help, grow business and provide for a family. On this particular 90-degree day, the vehicle was off the beaten path (literally an unpaved road) in the eastern Oregon desert hundreds of miles from town round-trip, leaving the tower to figure out a way to bring the vehicle back safely. So, he turned to his equipment – a wheel lift and Collins Dollies, confident that they could shoulder the load down the rough, dusty track. Confident because he’s done it before. Therefore, he chooses Collins Dollies.

135 miles – 35 of those through rough dirt roads, 100 highway miles. That is the recent log of a professional tower, one of many throughout the week that come in from motorists being stranded or local businesses servicing vehicles. Each one an opportunity to help, grow business and provide for a family. On this particular 90-degree day, the vehicle was off the beaten path (literally an unpaved road) in the eastern Oregon desert hundreds of miles from town round-trip, leaving the tower to figure out a way to bring the vehicle back safely. So, he turned to his equipment – a wheel lift and Collins Dollies, confident that they could shoulder the load down the rough, dusty track. Confident because he’s done it before. Therefore, he chooses Collins Dollies.

Collins Hi-Speed Dollies came about to increase the safety and speed that a vehicle could be recovered. Prior to that, dollies were completely assembled underneath a vehicle after using a jack to raise it high enough. Though a great invention for their time and capabilities, these pan dollies were heavy and exposed the operator to roadside hazards for an extended period because of the time it took to assemble. Collins Hi-Speed Dollies improved upon this concept and changed the towing industry with a self-loading dolly in 1972. Their Hi-Speed name is partly due to quicker setup and tow times since the dollies themselves were used to raise the vehicle.

Collins Hi-Speed Dollies came about to increase the safety and speed that a vehicle could be recovered. Prior to that, dollies were completely assembled underneath a vehicle after using a jack to raise it high enough. Though a great invention for their time and capabilities, these pan dollies were heavy and exposed the operator to roadside hazards for an extended period because of the time it took to assemble. Collins Hi-Speed Dollies improved upon this concept and changed the towing industry with a self-loading dolly in 1972. Their Hi-Speed name is partly due to quicker setup and tow times since the dollies themselves were used to raise the vehicle.

Collins Hassell, the namesake of Collins, had an entrepreneurial background gained through life’s experiences in creatively solving problems and caring for his family. During the 1940-50s while driving log trucks and hauling timber, Collins and his brother designed and manufactured improved log bunks and stakes for trucks that are still in use today. They had to be strong enough to carry a load of 50,000 pounds on trips from the forest to the mills, which could be a hundred miles or more (large portions of it on dangerous, washboard roads). Much of the materials and engineering for the bunks are like what would become the original self-loading dolly in 1972.

Collins Hassell, the namesake of Collins, had an entrepreneurial background gained through life’s experiences in creatively solving problems and caring for his family. During the 1940-50s while driving log trucks and hauling timber, Collins and his brother designed and manufactured improved log bunks and stakes for trucks that are still in use today. They had to be strong enough to carry a load of 50,000 pounds on trips from the forest to the mills, which could be a hundred miles or more (large portions of it on dangerous, washboard roads). Much of the materials and engineering for the bunks are like what would become the original self-loading dolly in 1972.

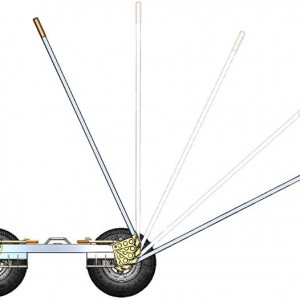

The self-loading dolly continues to evolve as material compositions and manufacturing technology progresses. Driven by user input—feedback from operators around the world contribute to what would help make their job easier, safer and equipment that is more resilient to road abuse. Some of these advancements led by Collins are:

1974 – Telescopic Positive Camber Steel Axles/Cross Rails

1974 – Greaseable Load-bearing Pivot Points Housed and Sealed Internally

1977 – Safety Ratchet System (SRS)

1985 – Safety Lock System

1995 – Telescopic Positive Camber Aluminum Axles/Cross Rails

1999 – Greaseable Steel Hubs

2006 – Lightest Weight Dolly (Collins Gen. 5 – SLX Hi-Speed Dolly)

2006 – Greaseable Aluminum Hubs

2006 – Removable Bolts & Components with Hand Tools

2008 – Aluminum 8” Wheel

2016 – Two-tone Zinc Plating Standard (Collins Gen. 6 – SLZ Hi-Speed Dolly)

2018 – Collins 4.80×8 Load Range D Tires (nearly 1000 lb. more capacity per set than 4.80 Load Range C Tires)

So, what does this mean for you? How many times have you needed a tool and been frustrated that you do not have it, cannot find it, isn’t the right one or it does not exist? Maybe you were able to make do with what you had (a refined skill among operators), but wish it had not taken extra time, reduced profit, or lost business. In recovery and repossession scenarios, this could look like: turning away potential clients, lost time calling additional trucks to move a vehicle because the first one could not handle it, risking personal injury or vehicle damage.

So, what does this mean for you? How many times have you needed a tool and been frustrated that you do not have it, cannot find it, isn’t the right one or it does not exist? Maybe you were able to make do with what you had (a refined skill among operators), but wish it had not taken extra time, reduced profit, or lost business. In recovery and repossession scenarios, this could look like: turning away potential clients, lost time calling additional trucks to move a vehicle because the first one could not handle it, risking personal injury or vehicle damage.

With the right equipment the job becomes easier and safer. Collins Dollies have been designed and built for:

- ease of use.

- safety for your team & customers.

- to go where you need to be.

One operator can load the dollies under a vehicle and quickly lift it. The quickest time we have encountered is 60 seconds, from off the truck to vehicle lifted! With a little training, an operator or agent can recover AWD, electric/hybrid, vehicles that are disabled or stuck in park using the same dollies and wheel lift to get all four wheels off the ground and the job done.

One operator can load the dollies under a vehicle and quickly lift it. The quickest time we have encountered is 60 seconds, from off the truck to vehicle lifted! With a little training, an operator or agent can recover AWD, electric/hybrid, vehicles that are disabled or stuck in park using the same dollies and wheel lift to get all four wheels off the ground and the job done.

Safety is a top priority in the industry and should not be left out of dolly towing. It’s why all Collins Hi-Speed Dollies include the Safety Ratchet System which allows an operator to safely lift a vehicle (light or heavy) in all conditions – rain, snow, ice, gravel, slopes, uneven terrain – with the operator in control even if they should lose their grip or footing. Without it, the operator remains in the dangerous impact zone of the pry bar’s arc and a wrong move potentially resulting in serious injury. The Safety Ratchet System (SRS) acts as a backup safety while under tow, to keep the vehicle upright. If a vehicle on dollies without the SRS drops while being towed, it could cause extensive damage. The ratchets can also assist in moving a vehicle that is up against a wall, garage, or similar obstacle by partly raising the dolly and vehicle, pulling the dolly away, then raising it completely.

Because you do not get to choose where or in what conditions the vehicle lies, it helps to have the proper equipment that works as hard as you do. Collins Dollies are built to handle inclement weather, rough road conditions, heavy loads and long-distance towing if required. Properly maintained, loaded, and secured, Collins Hi-Speed Dollies can safely be used on highways, freeways, and interstates to move the vehicle where you need to go. A single truck with a wheel lift and Collins Dollies can do the work of multiple trucks, increasing profitability.

Repossession agents can find a dolly model tailored to them — Collins Hi-Speed Dolly REPO. Lightweight for moving in and out of the bed of a truck, yet strongest in its class offering 3640 lb. of capacity on 4.80-D tires with steel wheels. Same high quality yet less aesthetic steel wheels make this an economic model. Paired with Collins Combo Mount, the Hi-Speed Dollies can be stored out of sight in the back of a; pickup bed yet within easy reach so they are accessible right when and where you need them. Looking ahead, Collins has another dolly model that has been in development over the last several years to make repossessing vehicles even quicker, so agents can be in and out, then down the road in as little time as possible.

For those operating a flatbed truck instead of a wrecker, Collins Carrier Dolly gives you a damage-free, efficient way to load and unload vehicles. They effectively raise the vehicle for greater ground clearance, make for quicker loading and unloading and opens possibilities for towing a wider range of cars – electric, AWD, high performance and luxury vehicles. Should you come across vehicles without wheels because they were stolen or removed to prevent repossession, the Tow Cradle fits both Hi-Speed Dollies and Carrier Dollies to support the rotor and allow for recovery.

For those operating a flatbed truck instead of a wrecker, Collins Carrier Dolly gives you a damage-free, efficient way to load and unload vehicles. They effectively raise the vehicle for greater ground clearance, make for quicker loading and unloading and opens possibilities for towing a wider range of cars – electric, AWD, high performance and luxury vehicles. Should you come across vehicles without wheels because they were stolen or removed to prevent repossession, the Tow Cradle fits both Hi-Speed Dollies and Carrier Dollies to support the rotor and allow for recovery.

Coming back to our tower in the desert, he earned the job and delivered the vehicle safely all from the comfort of his cooled truck. That same pair of Collins Dollies has assisted him in over 1000 miles of towing, in less than a month. With no sign of slowing, he can keep his business going. When safety, durability, longevity, better performance, lighter weight, and profitability all matter, he chooses Collins. Safe and happy towing!