There is a story—perhaps fictitious—that a successful businessman was asked how his company had prospered and grown, decade after decade. “There are two types of 50-year-old businesses,” he replied. “The first kind does not really have 50 years’ worth of experience. They have one year of experience, repeated 50 times. They survive, but do not prosper. The other kind of long-lived business is one that does not rest on its laurels, but constantly strives to do more, and do it better. My company is the latter type.”

There is a story—perhaps fictitious—that a successful businessman was asked how his company had prospered and grown, decade after decade. “There are two types of 50-year-old businesses,” he replied. “The first kind does not really have 50 years’ worth of experience. They have one year of experience, repeated 50 times. They survive, but do not prosper. The other kind of long-lived business is one that does not rest on its laurels, but constantly strives to do more, and do it better. My company is the latter type.”

Whether or not this story is true, the principle is still sound. No company can do the same old thing for 25, or 50, or 100 years and stay in business, let alone prosper. That is as true in the towing and recovery industry as it is in any other.

So, when we analyzed the story behind the 50th anniversary of Jerr-Dan, we expected to see evidence of a legacy of innovation and growth. Today, Jerr-Dan is an Oshkosh Corporation [NYSE: OSK] company and a leading manufacturer of towing and recovery equipment. Its full line includes light, medium, and heavy duty carriers and wreckers, rotators, industrial transporters, and four-car carriers. That is a far cry from what it looked like in 1972 when Jerry and Dan started the company.

EARLY DAYS

When Jerry Pool and Dan Reynolds founded Jerr-Dan in 1972, the company made parts for other companies’ equipment. They opened their first plant in Greencastle, Pennsylvania.

Later that year, Jerr-Dan purchased Grove Manufacturing Company’s agricultural industrial products division. As part of the purchase, they acquired their first rollback carrier technology. Although the Grove division they purchased mainly made farm trailers and related equipment, Grove had developed a flatbed rollback carrier just to be able to deliver their main product. From 1969 to 1972 Grove had even experimented with selling a small line of their rollback carriers. They decided that this was too far outside the scope of their core business, prompting the sale of the division to Jerr-Dan. While the carriers were the focus of Jerr-Dan’s interest even then, there are still some old pieces of farm equipment out there with the Jerr-Dan name on them.

With the company faring so well, the founders decided to tackle new challenges, each selling their interest in Jerr-Dan and founding their own new companies, Dan in 1973 and Jerry in 1992.

SPOTLIGHT ON INNOVATION SPARKS GROWTH

From the mid-70s to the late 90s, Jerr-Dan dedicated itself to providing a wider range of solutions for its customers as well as product innovations that would improve performance and reliability. Sometimes that meant improving on an existing design; at other times it meant designing something new from the ground up, and other times it meant acquiring a key company. A constant stream of substantive milestones were reached during this period.

In 1975, Jerr-Dan launched its own traveling axle trailer line in both 42- and 45-foot versions. The traveling axle design permits rear tires to slide forward so the bed can tilt to the ground, resulting in a more favorable loading angle.

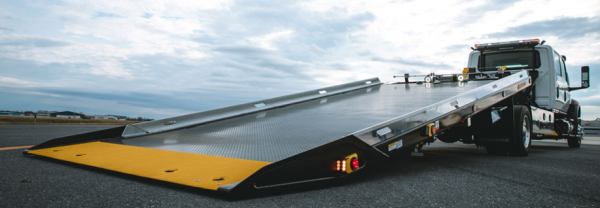

At around this time, Jerr-Dan engineers took note of the fact that all the larger vehicle carriers were built of steel and the weight of all that steel was putting extra stress on the truck chassis. Obviously, reducing the weight and the stress would extend the usable life of the truck— a big benefit to carrier owners. After research and some experimentation, the company decided to use an aluminum alloy in its new carrier design. Using this material would also help control corrosion. In 1977, Jerr-Dan launched the first commercially built aluminum carrier in the industry.

A few years later, Jerr-Dan product specialists were looking at a different problem. Metal on metal friction causes wear. And carriers had a metal bed sliding across a metal frame. When the wear became noticeable, the costly replacement of the bed or frame or both became necessary. The solution came in 1982 when Jerr-Dan received a patent for removable and replaceable wear pads. Metal on metal contact was now replaced with metal sliding across replaceable pads, extending the life of more expensive components.

In that same year, Jerr-Dan began production of the first extruded-aluminum plank carrier. Though this is now industry standard, it was a game-changer in the early 80s.

Close on the heels of those milestones, in 1985 Jerr-Dan launched the Jerr-Lift, the original self-loader. The Jerr-Lift secured the towed vehicle with hydraulic arms around the tires. It was the first offering of its kind in the traditional wrecker/recovery market. The Jerr-Lift reduced hook-up time and lessened operator fatigue.

In 1987 Jerr-Dan introduced the HPL, their first foray into a slightly larger light duty wrecker. Before releasing the new product to the market, Jerr-Dan decided to have an in-house competition to name it. At the time, most Jerr-Dan product names followed a “wild west” theme, with models named Rustler, Wrangler, and so on. (If you are old enough to remember the “urban cowboy” craze of the early 80s, you may understand this better. If not, just imagine a time when New York City accountants, bankers, and lawyers wore Stetsons on their heads and Tony Lamas on their feet. It was a different time.) But all the obvious cowboy-themed names had been used or weren’t available. However, a genius employee submitted perhaps the greatest product name of all time—HPL. That is, the “High Plains Lifter.”

In 1987 Jerr-Dan introduced the HPL, their first foray into a slightly larger light duty wrecker. Before releasing the new product to the market, Jerr-Dan decided to have an in-house competition to name it. At the time, most Jerr-Dan product names followed a “wild west” theme, with models named Rustler, Wrangler, and so on. (If you are old enough to remember the “urban cowboy” craze of the early 80s, you may understand this better. If not, just imagine a time when New York City accountants, bankers, and lawyers wore Stetsons on their heads and Tony Lamas on their feet. It was a different time.) But all the obvious cowboy-themed names had been used or weren’t available. However, a genius employee submitted perhaps the greatest product name of all time—HPL. That is, the “High Plains Lifter.”

The HPL line is still in production.

In the 90s, sports cars and the proliferation of other low-slung vehicles became more of a problem. With a standard flat deck carrier, towers had to build wooden ramps to create a suitable angle to load those low-profile vehicles. To address this issue, in 1992 Jerr-Dan designed, patented, and released the shark dual-angle rollback to the market. The angled end of the deck allowed it to load a lower-profile automobile without requiring a homemade ramp. Of course, in the 30 years since its introduction, Jerr-Dan has continued to add features and other improvements to the product.

By this time, the company had been in business for twenty years and was looking for a new growth opportunity. Jerr-Dan was building wreckers rated for light and medium duty but did not really have the experience or technology to enter the heavy duty wrecker market. However, that all changed in 1995 when the company bought DeWalt Manufacturing, a Texas-based company that built strictly heavy duty equipment for the recovery industry. The DeWalt acquisition brought with it the company’s patented hydraulic underlift. DeWalt product specialists brought their experience, skill, and knowledge as well. Jerr-Dan engineers credit the DeWalt designs for improving Jerr-Dan’s boom technology. With this key acquisition under its belt, Jerr-Dan was able to enter the 50ton heavy duty wrecker market with a fully developed product that had an established reputation.

The very next year, Jerr-Dan was able to build its original 25 ton heavy duty wrecker, that is, one not based on DeWalt’s design. It incorporated some new ideas about wrecker architecture that are a part of Jerr-Dan’s “DNA” to this day. The new wrecker was one of the first to introduce a composite body to the market on a commercial scale. It may seem obvious now, perhaps, but using an aluminum alloy frame with fiberglass panels to construct the body clearly results in less corrosion and a lighter and longer-lasting body. That added product longevity lowers total cost of ownership, then and now.

In 1997 Jerr-Dan launched a zero-degree underlift for carriers. It was a godsend to towers that had to contend with low-profile cars on steep surfaces—think the famously up and down streets of San Francisco. While most other lifts had a high loading angle, this new feature allowed the operator to put the wheel lift all the way down on the ground.

In 1997 Jerr-Dan launched a zero-degree underlift for carriers. It was a godsend to towers that had to contend with low-profile cars on steep surfaces—think the famously up and down streets of San Francisco. While most other lifts had a high loading angle, this new feature allowed the operator to put the wheel lift all the way down on the ground.

Around this same time, Jerr-Dan managers and engineers committed to overhauling their entire carrier line, and they wanted to have an internal standard for any resultant changes. They took a hard look at the carriers of their main competitors and realized right away that all had strong and weak points. So, they went out and bought a variety of other companies’ carriers and measured performance in key components and systems, the utility of various features, and so on.

After carrying out a full analysis of what could be viewed as the industry’s state of the art in carriers, Jerr-Dan created its Best in Class (BIC) carrier line. This new line of carriers was benchmarked to the best performance in each category of operation and was built to meet or exceed them. Introduced in 1998, Jerr-Dan felt confident that “BIC” carriers set the standard. Future improvements to Jerr-Dan carriers would be based on the BIC platform and philosophy.

In 1999 Jerr-Dan launched its first 14- and 16-ton heavy duty wreckers. These new wreckers fit on a class 7 chassis, giving them more flexibility in the market.

1999 brought even more changes to Jerr-Dan when it was acquired by Littlejohn & Company. Littlejohn & Company was, and still is, a private equity firm that makes control equity investments in mid-sized companies that can benefit from its operational and strategic experience. Jerr-Dan was ready to open a new chapter in its story just as the world was poised to open a new century.

A NEW CENTURY BRINGS NEW OPPORTUNITIES

The previous quarter-century had seen a lot of improvements in the company and its products. The arrival of the 21st century only accelerated this trend.

In 2001, Jerr-Dan received a patent for a unique tow-locking mechanism. It was common practice to use hydraulics to secure the tow arms when they closed around tires. Jerr-Dan engineers were all too aware that hydraulics could be compromised by a loss of fluid or pressure. They solved the problem by adding a mechanical lock. They would still use hydraulics to move the arms into position, but the mechanical lock would continue to secure the tire even if the hydraulics failed at some point during the tow.

Then, in 2002, Jerr-Dan received another patent, this time for an independent wheel-lift. This wheel-lift was made independent of the wrecker-boom by using the knee-boom, so named due to its resemblance to a bent knee.

However, 2004 would prove to be the most pivotal year of the new century for Jerr-Dan. That was the year it was acquired by the Oshkosh Corporation.

The new owner had the size, resources, and strategic direction that would permit Jerr-Dan to accomplish more, faster. Today, Oshkosh Corporation employs nearly 15,000 team members worldwide, and its products are found in more than 150 countries. Jerr-Dan had joined a family of brands that today includes other top-tier brands, such as JLG®, Pierce®, Oshkosh® Defense, McNeilus®, IMT®, Frontline™, Oshkosh® Airport Products, London™, and Pratt Miller.

At this point, there was really only one piece of equipment that the Jerr-Dan product range lacked—a rotator. But the company had been working with customers behind the scenes to get their input on building the “ultimate rotator.” For several years Jerr-Dan had interviewed owners and operators and relied on their suggestions to continually improve a new rotator design. Many mentioned a desire to reach more and get into position more easily. And it was no surprise to learn that almost everyone was concerned about improving stability.

Jerr-Dan took all these suggestions to heart, and in 2005 introduced the Jerr-Dan Rotator. This product debuted with a conservative 60ton rating but when applied to real-life situations ended up as the Jerr-Dan 70/85ton, heavy duty rotator. Backed by Jerr-Dan engineering and performance, users were able to reach further and position their boom more easily because of the new machine’s 42-foot working radius, at a time when the nearest competitor only offered 34 feet. What set the unit apart was its industry-leading stability, achieved through the widest dual scissor-style outrigger system of its time coupled with the strongest rotator frame in the industry. This knowledge and technology would guide Jerr-Dan to offer the industry’s hallmark 50/60-ton rotator in 2011.

In 2008 Jerr-Dan received another important patent. This patent was for the SRS, or “Side Recovery System.” The company had been looking at ways to improve its recovery capabilities, and the SRS certainly helped them reach that goal. The concept is simple—the boom would easily rotate to the left or right to enable recovery on either side of the tow vehicle. This new product was available as an option on new trucks, or as an aftermarket add-on for older trucks. Unlike most of the patented products that preceded it, Jerr-Dan made the SRS available to their dealers to be fitted to competitors’ trucks.

Jerr-Dan closed out the first decade of the 21st century with another addition to its carrier line. The new XLP (extra-low profile) carriers addressed the continuing need to lower the height of beds. This new line of carriers was also designed to be mounted without having to modify the truck itself, a feature that dealers especially appreciated. Over the next ten years, these XLP features were extended to all carrier sizes in the product range.

And in 2011, Jerr-Dan kicked off the second decade of the century with a major step forward. To improve efficiency, Jerr-Dan moved all its manufacturing to facilities in McConnellsburg, Pennsylvania.

When taking note of relatively recent technical accomplishments, attention must be given to the patents the company received in 2013 for improved deck illumination and adjustable headboards for carriers. The adjustable headboards were a consequential boon for dealers, making the job of installation much simpler. Obviously, each truck has a cab height that is unique to it. That meant that a manufacturer had to build a different headboard for every truck, and dealers had to manage their inventory of all those unique headboards. With the introduction of the adjustable headboard, Jerr-Dan was able to reduce that inventory to just two sizes of headboard for all carrier models and chassis cab heights.

The second patent that year, the Rear Awareness Illumination Light (RAIL), was all about improving roadside visibility in all circumstances. Based on their intimate knowledge of the industry, product specialists and engineers were aware that when a carrier parks in front of a vehicle casualty, its warning lights are often obscured. In some cases, they almost seem to disappear. Jerr-Dan addressed this issue by adding lights that extended beyond the profile of the truck facing rearward. RAIL also optimized the lighting for the greatest visibility when the bed was tipped down, the point at which traditional lighting schemes are most obscured.

Keeping the focus on simplifying an operator’s work, in 2014 Jerr-Dan received a patent for a new vehicle storage assembly, as part of its new JFB heavy duty wrecker and Rotator body line. This was the start of a renewed push to conform to the principle reportedly first articulated by Benjamin Franklin: “a place for everything, everything in its place.”

With the corporate strategy, company growth, and distributor network all working together, by 2017 it was time to add financial services to the company’s portfolio of expertise and customer service. In that year, Jerr-Dan launched Jerr-Dan Financial Solutions (JDFS) to provide customers with a one-stop shopping experience.

Interestingly, Jerr-Dan Financial Solutions is more than just a financial team. JDFS is made up of tow truck operators as well as sales and finance professionals who know the towing and recovery industry inside and out. According to Jerr-Dan Financial Services, “We offer competitive interest rates and no down payment for qualified buyers. Lease or loan packages are available with terms from 24 to 84 months. We also provide a 24-hour turnaround on all credit applications.”

And finally, the most impressive milestone of all—Jerr-Dan is celebrating 50 years in business in 2022.

DRIVING FORWARD INTO THE FUTURE

“People have asked us what we have in the works,” said Jerr-Dan senior product specialist Andrew Stevens. “Obviously, that is a question I am not free to answer in any detail. But I can tell you that we are committed to improving existing models—the updated JD25 is one recent example. And we are committed to listening to our customers’ needs. Those are the conversations that end up as the inspiration for exciting new product developments.”

Chief Engineer Sanjeev Kuriakose also addressed Jerr-Dan’s future goals. “Besides building equipment that works as hard as our customers do, we want to promote the hardworking men and women of this industry so they get the respect they deserve and are seen and treated as professionals. There are a lot of owners and operators out there leading the way, and we want to do whatever we can to aid them. We believe proper training is the key. It’s more than promoting Jerr-Dan Equipment. It’s about helping towers work smarter, safer and getting them home to enjoy their families when the work is done.”

No one can foretell the future of the economy, let alone the future of a particular company. The Great Recession and COVID-19 have provided recent and stark examples of this truth. However, it is possible to make projections based on past performance. On that basis, it is not hard to look forward to Jerr-Dan’s 75th and 100th anniversaries.

For more information, visit www.jerrdan.com.