Last month, I received a call to help a dear family in the recycling business that needed some big-time help and they needed it fast. They were desperate to remove a Jeep from one of the areas that was in the pathway of the worst damage to hit from a recent hurricane in South Florida.

It was late in the afternoon when I received their anxious text message, “Is there ANY WAY you know someone in towing in South Florida that can move Jeff and Janice’s Jeep?” The text was from Roger Schroder. Roger co-founded Car-part.com along with his brother Jeff.

Car-part.com and the Schroders family are two of the best things that have happened to this old man. I’ve come to know the Schroder family as a kind and generous group of people. Many years ago, when my daughter was getting married at the Bellagio in Las Vegas, I was just shy of raising enough money to cover the deposit. The Schroder family saved the day for us and sent an early wedding gift which covered what I couldn’t at the time.

When Roger texted, he told me that they had been notified by the marina that the hurricane in South Florida mostly likely would take their Jeep for a ride with no-one in it. All tows being done were “Emergency only” tows. Unless it was life or death to get it moved, that Jeep was as good as gone. Not a great response in a time of crisis, huh? So, I texted back, “I’m on it!” and got to work making it happen. My first call was to my dear friend, Todd Stepp, of Stepp’s Towing on his private cell number. When I told him the story, Todd immediately sent information to Mike McArthur, his Director of Towing Operations. Mike has been with Stepps 24 years. Within minutes Mike called me, “DJ, we are 2 and a half hours from where the Jeep is located. But, if we can’t find a fellow tower within the next hour, we will send a truck and store the Jeep here in Pinellas County until the hurricane passes.” Upon hearing this, we both got to work. Surely someone who was closer could help.

This is important to understand. The first call, near the Jeep’s location, the tower I spoke to said, “First, we are only doing emergency tows, police directed, plus we don’t store any vehicles at our facility.” The next guy said that he stored vehicles, but his truck was out of service. Both calls couldn’t help me.

Then, I called a big-time tower that all of us know and the dispatch service informed me that the owner was not there, “but was smart by hunkering down for the hurricane.” I must admit that her additional answer made my mouth drop when she said, “they should have thought about moving the Jeep 3 days earlier. I guess your friends are not that smart. Sir, kiss that Jeep good bye,” and then hung up on me.

So, after a few more calls, I spoke with Gay Rochester, President of INA Towing Network, you know the big group that tows for Amazon, Lowes, Home Depot, Red Cross, etc. Gay knows the Schroder family from back in 2017 when Car-part.com had to move 56 cars out of the flood zone during Hurricane Harvey in Houston, Texas. Gay’s company, INA, moved all the vehicles in less than 42 hours. Many towers, when pushed to the limit, can perform extraordinarily well during emergencies. So, Gay took the information while I also kept dialing.

I spoke at Jim Stepp’s memorial service back in April of 2017. Jim was Todd’s dad and started Stepp’s Towing back in 1960 from a gas station in Temple Terrace, Florida. Now Stepp’s has over 150 trucks. Many locations later, Jim’s memory lives on. I carry Jim’s coin of remembrance in my pocket and recently showed it to his grandson at the Florida Tow Show.

Mike at Stepps told me to call Prompt Towing, located in Charlotte County, Florida and ask for Joey. All of us know Joey Saladino. A great guy! The man who answered my call was Edward Canfield. I told him, “I’m calling from Atlanta, Georgia. My name is DJ Harrington…” and stopped me mid-sentence, “The same guy that writes for the Tow Professional Magazine and does podcasts for the magazine and the one for Wes Wilburn?” Shocked at his response, I said, “Hell, yes, the same one!” I knew I liked Edward right off. I told him about the Jeep and the need to move it quickly, but he said, “Tell the Schroder’s that just this past Monday, we ordered a Chrysler 300 Bumper from Car-Part.pro, one of their divisions. This former police officer and Eagle Scout, had the Jeep back in his yard within 2 hours.

Here is a picture of the Jeep, safe and sound the next day. Edward called to say that he had spoken to Janice, Jeff’s wife, and said that she was very nice lady who appreciated their great service. Edward knew Janice had to be a special person because they were bringing the Jeep back to their towing yard. When INA called him to tow the same Jeep, it was already on the truck. So, he told Janice that she must be some kind of a celebrity.

Thank you goes to Edward and the whole team at Prompt Towing for their swift service. I certainly, don’t want to forget the President of Prompt Towing, Sharon Murray along with Mike and Todd Stepp. As you would expect, the following day I received a thank you from Roger, Jeff and Janice Schroder. Jeff said that he was glad that all of my towing friends got involved with moving a Jeep without the help of keys because it truly was stuck on a marina, destined for destruction from a monstrous hurricane.

In my book, Edward Canfield deserves the Most Knowledgeable Tow Person of the Year award. Most importantly, having great friends is invaluable when you really need them.

See you on the next podcast.

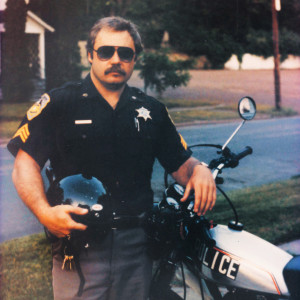

What makes towers do what they do? Are they born this way or trained this way? Maybe a little of both? Towers are a special kind of person.

What makes towers do what they do? Are they born this way or trained this way? Maybe a little of both? Towers are a special kind of person.

While with the Sheriff’s Dept, he also formed the companies Photo Card Specialists, Inc. and Awards & More, Co. currently celebrating 37 years in business. For 36 years, Terry and Linda traveled nationwide to Tow Shows developing many connections in the towing industries and gaining close friends. He loved photographing trucks and visiting with the owners, drivers, and families.

While with the Sheriff’s Dept, he also formed the companies Photo Card Specialists, Inc. and Awards & More, Co. currently celebrating 37 years in business. For 36 years, Terry and Linda traveled nationwide to Tow Shows developing many connections in the towing industries and gaining close friends. He loved photographing trucks and visiting with the owners, drivers, and families.