Big personal insurance companies spend billions each year on TV ads convincing people that price is all that matters when shopping for insurance. In the commercial world, that is horrible advice. Instead of shopping for the cheapest insurance, you should be shopping for the right insurance agent. Just like not all insurance is the same, not all agents are the same. Towing is a niche market for us because Hal Kresser, the agency principal, is very interested in the industry. He worked for a towing service when he was young and even today he is Wreckmaster Level II certified and can operate your equipment. Can your current agent do that? Hal is also involved in the industry. He is an active, participating member of the Towing and Recovery Association of Ohio. In fact, he is so well respected that he was nominated and elected to be president of the local region and is currently serving his fifth term. Before he was an insurance agent he spent 20 years as a cop. He is certified in accident reconstruction and knows the laws and how to deal with police officers. He’s good to have as an advocate in some of the collision claims that happen when there are disputes as to fault and he can help you decide when to fight traffic tickets and violations and when not. For example, we had one two years ago where a person on a bicycle rode into the side of a rollback that was making a right turn. The police officer listed the driver at fault for violating a crosswalk. After talking to the driver, Hal learned that the bike hit the truck by the back axel. That meant the truck was almost fully through the turn before being struck. That makes it the bicyclist’s fault. He contacted the traffic supervisor and discussed how the report was improperly written and explained why it was not the driver’s fault. The supervisor agreed and got the officer to re-write the report correctly. This saved the customer from having a chargeable accident on his record and saved the insurance company from paying a personal injury claim. Claim adjustors are trained to take a police report as gospel. Unfortunately, not all crash reports are written correctly. Hal has the experience to know and can help when it happens to keep our clients from being unjustly charged with accidents.

Big personal insurance companies spend billions each year on TV ads convincing people that price is all that matters when shopping for insurance. In the commercial world, that is horrible advice. Instead of shopping for the cheapest insurance, you should be shopping for the right insurance agent. Just like not all insurance is the same, not all agents are the same. Towing is a niche market for us because Hal Kresser, the agency principal, is very interested in the industry. He worked for a towing service when he was young and even today he is Wreckmaster Level II certified and can operate your equipment. Can your current agent do that? Hal is also involved in the industry. He is an active, participating member of the Towing and Recovery Association of Ohio. In fact, he is so well respected that he was nominated and elected to be president of the local region and is currently serving his fifth term. Before he was an insurance agent he spent 20 years as a cop. He is certified in accident reconstruction and knows the laws and how to deal with police officers. He’s good to have as an advocate in some of the collision claims that happen when there are disputes as to fault and he can help you decide when to fight traffic tickets and violations and when not. For example, we had one two years ago where a person on a bicycle rode into the side of a rollback that was making a right turn. The police officer listed the driver at fault for violating a crosswalk. After talking to the driver, Hal learned that the bike hit the truck by the back axel. That meant the truck was almost fully through the turn before being struck. That makes it the bicyclist’s fault. He contacted the traffic supervisor and discussed how the report was improperly written and explained why it was not the driver’s fault. The supervisor agreed and got the officer to re-write the report correctly. This saved the customer from having a chargeable accident on his record and saved the insurance company from paying a personal injury claim. Claim adjustors are trained to take a police report as gospel. Unfortunately, not all crash reports are written correctly. Hal has the experience to know and can help when it happens to keep our clients from being unjustly charged with accidents.

When you choose the right agent, he will be able to place you with an insurance carrier that best suits your needs. As an independent agent we have the ability to add new companies that enter the market. We have seen companies come into the towing market for a few years and then get back out. When that happens, you can lose your insurance through no fault of your own. A good agent is on top of that and can make transitioning to another carrier seamless. You need to build a relationship with your agent. He can help you decide when to file a claim or when to pay out of pocket. He can advise you on ways to keep your rates down as well as help you implement plans to avoid liability claims. We recommend things like putting cameras in the trucks to document crashes. They can be invaluable in situations where fault is in dispute.

Choose the right agent and build the relationship on trust and integrity. The agent should be viewed as a stakeholder in your business. In a recent Google review of our agency, Tiffany Corey of John Wayne Towing wrote “even when we were told there was no hope by everyone else, they didn’t give up and kept pushing forward. I work for John Wayne Towing and we are a small company so something as major as insurance can really make or break a company. So, if you are needing insurance, I would highly recommend giving them a chance.” You need a good, well managed insurance portfolio to help your business be successful and the agent needs your business to be successful to make his business successful. If you are contemplating any big expansion plans such as adding a new building or moving to a larger facility in another part of town, or adding more trucks you should involve your agent during the planning stage to find out in advance what the impact on the insurance will be. Many times, I get the call to add something like a building, a second location, or a 50 ton rotator to the policy after the fact. Then the insured is upset when he sees how much it costs. Now it’s too late.

Choose the right agent and build the relationship on trust and integrity. The agent should be viewed as a stakeholder in your business. In a recent Google review of our agency, Tiffany Corey of John Wayne Towing wrote “even when we were told there was no hope by everyone else, they didn’t give up and kept pushing forward. I work for John Wayne Towing and we are a small company so something as major as insurance can really make or break a company. So, if you are needing insurance, I would highly recommend giving them a chance.” You need a good, well managed insurance portfolio to help your business be successful and the agent needs your business to be successful to make his business successful. If you are contemplating any big expansion plans such as adding a new building or moving to a larger facility in another part of town, or adding more trucks you should involve your agent during the planning stage to find out in advance what the impact on the insurance will be. Many times, I get the call to add something like a building, a second location, or a 50 ton rotator to the policy after the fact. Then the insured is upset when he sees how much it costs. Now it’s too late.

To learn more call Hal Kresser today! 877-412-3434 or email him hal@kresseragency.com.

R

R In addition, Urgently requires service providers to maintain standards that set them apart: things like a minimum level of insurance, experience, customer ratings, branded uniforms and vehicles, background checks, service technician photos and information shared with motorists in advance.

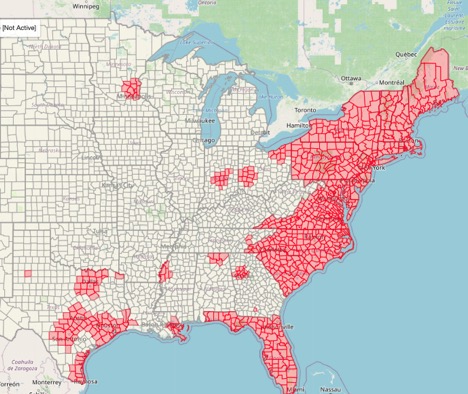

In addition, Urgently requires service providers to maintain standards that set them apart: things like a minimum level of insurance, experience, customer ratings, branded uniforms and vehicles, background checks, service technician photos and information shared with motorists in advance. Service providers also benefit from being part of the Urgently network. Urgently supports the network with tools and training to help service providers adapt to changes in the mobility market and take advantage of opportunities to grow their business. In a recent survey of service providers, Service partners that are embracing new technology like Urgently are experiencing above average growth. Urgently also ranked at the top for providing the best overall experience for service providers, for proximity to jobs, dispatch portal, payment process, technology and support. Urgently was also identified as the roadside assistance brand service providers would most likely recommend to a friend or colleague.

Service providers also benefit from being part of the Urgently network. Urgently supports the network with tools and training to help service providers adapt to changes in the mobility market and take advantage of opportunities to grow their business. In a recent survey of service providers, Service partners that are embracing new technology like Urgently are experiencing above average growth. Urgently also ranked at the top for providing the best overall experience for service providers, for proximity to jobs, dispatch portal, payment process, technology and support. Urgently was also identified as the roadside assistance brand service providers would most likely recommend to a friend or colleague.

M

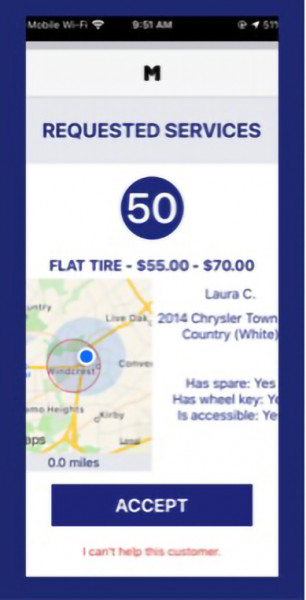

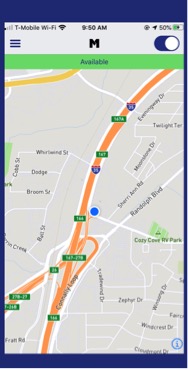

M There is no need to provide your business hours. Providers simply mark themselves available or unavailable if they are done for the day.

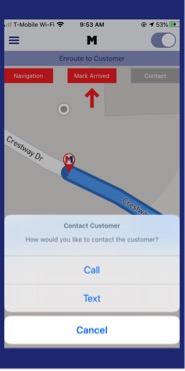

There is no need to provide your business hours. Providers simply mark themselves available or unavailable if they are done for the day. The customer signs the providers device and then the money is transferred automatically from the customer to the providers payment account every 24 hours (48 rolling). An invoice is created automatically as well so there is zero paperwork.

The customer signs the providers device and then the money is transferred automatically from the customer to the providers payment account every 24 hours (48 rolling). An invoice is created automatically as well so there is zero paperwork.  We’re a hard working, veteran owned company, trying to change the industry for your good. If all this sounds good to you, don’t wait to get started! We are onboarding providers across the U.S. and are opening new cities quickly.

We’re a hard working, veteran owned company, trying to change the industry for your good. If all this sounds good to you, don’t wait to get started! We are onboarding providers across the U.S. and are opening new cities quickly.

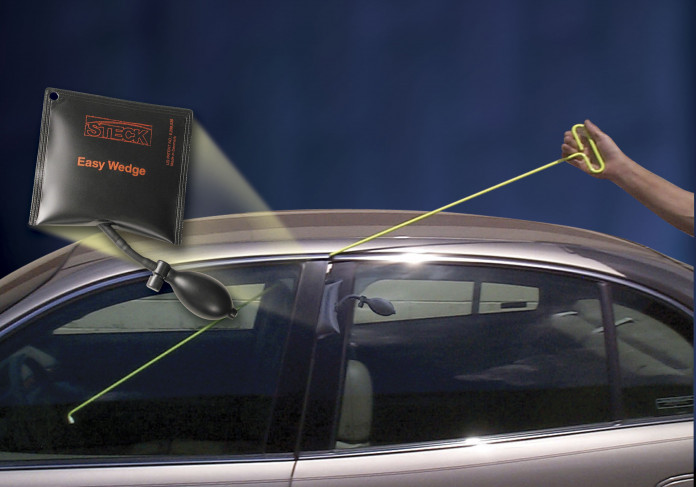

Tow Drivers unlock cars in seconds without damaging car doors by using Steck Manufacturing’s BigEasy Lockout Tool. Over the last 15 years this one tool has become the tool of choice for tow truck drivers. It is simple to use by first inserting the Easy Wedge into the top of the door to allow enough room to then insert the BigEasy tool to press or hook the door lock from inside the window rather than using the door panel. The ease of the BigEasy to open doors from inside the window reduces liability issues with traditional lockout tools which have the potential to disable wiring systems inside the door panel.

Tow Drivers unlock cars in seconds without damaging car doors by using Steck Manufacturing’s BigEasy Lockout Tool. Over the last 15 years this one tool has become the tool of choice for tow truck drivers. It is simple to use by first inserting the Easy Wedge into the top of the door to allow enough room to then insert the BigEasy tool to press or hook the door lock from inside the window rather than using the door panel. The ease of the BigEasy to open doors from inside the window reduces liability issues with traditional lockout tools which have the potential to disable wiring systems inside the door panel.

We also have many accessories to assist the Tower and shops like our new 4th Wheel Loader (71480) to assist moving vehicles with damaged wheels, Tie Rod Pliers (71465) and Tie Rod Coupler (71470) for temporary steering assistance.

We also have many accessories to assist the Tower and shops like our new 4th Wheel Loader (71480) to assist moving vehicles with damaged wheels, Tie Rod Pliers (71465) and Tie Rod Coupler (71470) for temporary steering assistance.

S

S The One Hand Jack and Super One Hand Jack are unique wedges that function as pry-bars grabbing just the lip of the door frame avoiding any contact with the weather stripping or other delicate parts of the door typically damaged by traditional wedges.

The One Hand Jack and Super One Hand Jack are unique wedges that function as pry-bars grabbing just the lip of the door frame avoiding any contact with the weather stripping or other delicate parts of the door typically damaged by traditional wedges. Other tools in the industry are painted or powder-coated which easily scratches a vehicles delicate painted surface. A long reach tool can be used to pull a door handle, push an unlock button, pull a trunk or hood release lever, push a key fobs buttons, or grab a keyring.

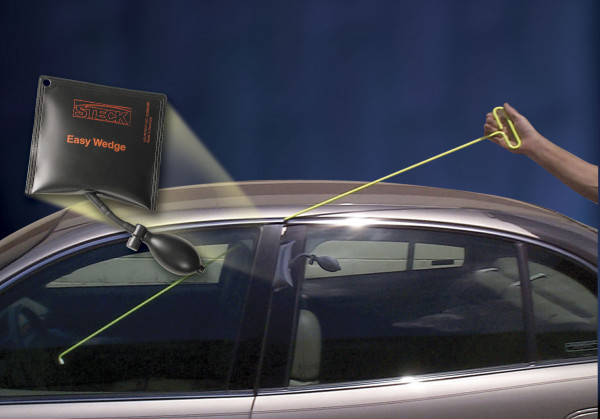

Other tools in the industry are painted or powder-coated which easily scratches a vehicles delicate painted surface. A long reach tool can be used to pull a door handle, push an unlock button, pull a trunk or hood release lever, push a key fobs buttons, or grab a keyring. Each of the four sizes of the Air Jack air wedges from Access Tools are manufactured of ballistic nylon, which makes them extremely durable. They feature unique rounded edges, which in combination with the internal stiffener, make any Access Tools air wedge easy to insert into a vehicle without risk of damage to the delicate weather stripping. The extremely durable ballistic nylon is double sealed at all seams, making them leak proof and strong enough to last for many years without failure.

Each of the four sizes of the Air Jack air wedges from Access Tools are manufactured of ballistic nylon, which makes them extremely durable. They feature unique rounded edges, which in combination with the internal stiffener, make any Access Tools air wedge easy to insert into a vehicle without risk of damage to the delicate weather stripping. The extremely durable ballistic nylon is double sealed at all seams, making them leak proof and strong enough to last for many years without failure. The standard Button Master, Stainless Steel Button Master, Heavy Duty Button Master, and extra-long Mega Master all feature the same protective coating as the other Access Tools Long Reach Tools. These tools are extremely flexible and allow the user to bend the tool into any desired position for any vehicle application. They all feature improved internal no-curl wire technology that enables these tools to open thousands of vehicles during their lifetime.

The standard Button Master, Stainless Steel Button Master, Heavy Duty Button Master, and extra-long Mega Master all feature the same protective coating as the other Access Tools Long Reach Tools. These tools are extremely flexible and allow the user to bend the tool into any desired position for any vehicle application. They all feature improved internal no-curl wire technology that enables these tools to open thousands of vehicles during their lifetime. The Glassman Wedge is designed specifically for frameless window vehicles such as high-end BMWs, Mercedes, and other convertible vehicles. These vehicles are susceptible to easily broken windows when using traditional wedge methods, and so the Glassman Wedge functions as a protective double-sided wedge that distributes the force of your long reach tool over a wide surface of the glass, reducing the chances of shattering an expensive window.

The Glassman Wedge is designed specifically for frameless window vehicles such as high-end BMWs, Mercedes, and other convertible vehicles. These vehicles are susceptible to easily broken windows when using traditional wedge methods, and so the Glassman Wedge functions as a protective double-sided wedge that distributes the force of your long reach tool over a wide surface of the glass, reducing the chances of shattering an expensive window.

T

T

We’ll start with the granddaddy of jump starter power supplies. The key benefits of lead acid when it comes to jump starting are its ability to deliver high power, ability to deliver extended cranking durations, ability to perform in cold temperatures, ability to withstand abuse and ability to hold its charge for extended periods and still be useful for jump starting. The biggest drawbacks of the lead acid option are weight and size. It is definitely the heaviest of the jump starting options and typically the bulkiest.

We’ll start with the granddaddy of jump starter power supplies. The key benefits of lead acid when it comes to jump starting are its ability to deliver high power, ability to deliver extended cranking durations, ability to perform in cold temperatures, ability to withstand abuse and ability to hold its charge for extended periods and still be useful for jump starting. The biggest drawbacks of the lead acid option are weight and size. It is definitely the heaviest of the jump starting options and typically the bulkiest. Lithium jump starters have been around in commercial

Lithium jump starters have been around in commercial  Ultracapacitor jump starters provide a totally different power profile than lead acid or lithium jump starters making them great for some operations but likely less desirable for others. The key benefits of ultracapacitor jump starters are their massive power to weight ratio, their exceptional cold temperature performance, the speed with which they give their power to the jump starting application (more power faster is always better) and their exceptional longevity. The biggest drawbacks of the ultracapacitor option are their lack of reserve capacity and the speed with which they discharge (don’t hold a charge for long).

Ultracapacitor jump starters provide a totally different power profile than lead acid or lithium jump starters making them great for some operations but likely less desirable for others. The key benefits of ultracapacitor jump starters are their massive power to weight ratio, their exceptional cold temperature performance, the speed with which they give their power to the jump starting application (more power faster is always better) and their exceptional longevity. The biggest drawbacks of the ultracapacitor option are their lack of reserve capacity and the speed with which they discharge (don’t hold a charge for long). Every operation is different. What works for one company/operator won’t necessarily work for another. Cost sensitivity can vary from operation to operation. When choosing a jump starter, start with your specific requirements. Are your starting 1-5 vehicles per day or 10-20 vehicles? What are the sizes of the typical engines you are starting? What weather conditions do you encounter? (I spoke to an operator in Northern Alberta, Canada this morning. His concern for -50˚F temperatures is not relevant for an operator in Tampa, Florida.) What is your recharging situation – will you go long periods of use between charging opportunities? How experienced is your team? Do you need other functions or are you looking for a tool specifically for jump starting? Determining the answers to these questions will help identify the option that best addresses your specific jump starting needs.

Every operation is different. What works for one company/operator won’t necessarily work for another. Cost sensitivity can vary from operation to operation. When choosing a jump starter, start with your specific requirements. Are your starting 1-5 vehicles per day or 10-20 vehicles? What are the sizes of the typical engines you are starting? What weather conditions do you encounter? (I spoke to an operator in Northern Alberta, Canada this morning. His concern for -50˚F temperatures is not relevant for an operator in Tampa, Florida.) What is your recharging situation – will you go long periods of use between charging opportunities? How experienced is your team? Do you need other functions or are you looking for a tool specifically for jump starting? Determining the answers to these questions will help identify the option that best addresses your specific jump starting needs.

Custer Products offers a wide variety of different products for your service trucks. From wireless light bars to replacement marker lights, Custer has all of your lighting needs. One of Custer’s newest products is the 54-Watt work light/amber strobe combo light (WL54AW). Similar to Custer’s WL19F in size and shape, the WL54AW includes a 27-watt white work light in the bottom row of diodes and a 27-watt amber strobe light on the top. This light includes a 3-wire hook-up which allows the driver to operate the strobe and work light features independently.

Custer Products offers a wide variety of different products for your service trucks. From wireless light bars to replacement marker lights, Custer has all of your lighting needs. One of Custer’s newest products is the 54-Watt work light/amber strobe combo light (WL54AW). Similar to Custer’s WL19F in size and shape, the WL54AW includes a 27-watt white work light in the bottom row of diodes and a 27-watt amber strobe light on the top. This light includes a 3-wire hook-up which allows the driver to operate the strobe and work light features independently.  Custer Products carries an entire line of wireless tow lights to help keep our tow truck drivers safe. The newest addition to Custer’s wireless line is the 23” wireless light-duty tow light (LIW-LDTL). This bar was designed with tow truck drivers in mind. Designed to withstand even the most inclement weather conditions, the polyethylene case is nearly indestructible and won’t warp or crack. The steel handle on top and the 105 lb. pull rubber-coated magnets on the bottom make for easy on-and-off installation while its low-profile design saves room in storage. Just like all of Custer’s wireless light bars, this bar is individually serialized which eliminates cross-talk between units and protects the owner against theft. This bar meets all DOT requirements, comes with a 3-year warranty and is proudly manufactured at Custer Products’ facility in Massillon OH.

Custer Products carries an entire line of wireless tow lights to help keep our tow truck drivers safe. The newest addition to Custer’s wireless line is the 23” wireless light-duty tow light (LIW-LDTL). This bar was designed with tow truck drivers in mind. Designed to withstand even the most inclement weather conditions, the polyethylene case is nearly indestructible and won’t warp or crack. The steel handle on top and the 105 lb. pull rubber-coated magnets on the bottom make for easy on-and-off installation while its low-profile design saves room in storage. Just like all of Custer’s wireless light bars, this bar is individually serialized which eliminates cross-talk between units and protects the owner against theft. This bar meets all DOT requirements, comes with a 3-year warranty and is proudly manufactured at Custer Products’ facility in Massillon OH. One of Custer’s highest selling product lines is their LED rooftop light bars. Custer offers everything from 11’’ miniature rooftop light bars to 72” full size light bars. One of the newest additions to the rooftop light bar line is the LED Amber/White rooftop light bar which is available in 29”, 56”, and 72” lengths to fit several different sizes of service trucks. This strobe light bar comes with thirty flash patterns all controlled from a multi-function control box that sits in the cab of the truck. This bar comes with arrow stick/traffic control built in with seven different

One of Custer’s highest selling product lines is their LED rooftop light bars. Custer offers everything from 11’’ miniature rooftop light bars to 72” full size light bars. One of the newest additions to the rooftop light bar line is the LED Amber/White rooftop light bar which is available in 29”, 56”, and 72” lengths to fit several different sizes of service trucks. This strobe light bar comes with thirty flash patterns all controlled from a multi-function control box that sits in the cab of the truck. This bar comes with arrow stick/traffic control built in with seven different  Along with rooftop strobe light bars, Custer Products also sells a wide variety of surface mount strobes. One of the newest additions to Custer’s line is the LED Class I Surface mount strobe (STR-XL1) which is available in Amber (not pictured) and Amber/White. With very low-profile dimensions of 4.85” L x 1” W x 0.3” D, the STR-XL1 series is small in size but powerful in its brightness. This strobe light comes with 24 different flash patterns and can be synchronized with up to twelve other modules of its kind. The STR-XL1 series is also able to do an alternating pattern or a “wig-wag” function with another light. This reverse polarity protected strobe light comes with a Class I SAE certification and has a waterproof rating

Along with rooftop strobe light bars, Custer Products also sells a wide variety of surface mount strobes. One of the newest additions to Custer’s line is the LED Class I Surface mount strobe (STR-XL1) which is available in Amber (not pictured) and Amber/White. With very low-profile dimensions of 4.85” L x 1” W x 0.3” D, the STR-XL1 series is small in size but powerful in its brightness. This strobe light comes with 24 different flash patterns and can be synchronized with up to twelve other modules of its kind. The STR-XL1 series is also able to do an alternating pattern or a “wig-wag” function with another light. This reverse polarity protected strobe light comes with a Class I SAE certification and has a waterproof rating

135 miles – 35 of those through rough dirt roads, 100 highway miles. That’s the recent log of a professional tower, one of many throughout the week that come in from motorists being stranded or local businesses servicing vehicles. Each one an opportunity to help, grow business and provide for a family. On this particular 90-degree day, the vehicle was off the beaten path (literally an unpaved road) in the eastern Oregon desert hundreds of miles from town round-trip, leaving the tower to figure out a way to bring the vehicle back safely. So he turned to his equipment – a wheel lift and Collins Dollies, confident that they could shoulder the load down the rough, dusty track. Confident because he’s done it before. It’s why he chooses Collins Dollies.

135 miles – 35 of those through rough dirt roads, 100 highway miles. That’s the recent log of a professional tower, one of many throughout the week that come in from motorists being stranded or local businesses servicing vehicles. Each one an opportunity to help, grow business and provide for a family. On this particular 90-degree day, the vehicle was off the beaten path (literally an unpaved road) in the eastern Oregon desert hundreds of miles from town round-trip, leaving the tower to figure out a way to bring the vehicle back safely. So he turned to his equipment – a wheel lift and Collins Dollies, confident that they could shoulder the load down the rough, dusty track. Confident because he’s done it before. It’s why he chooses Collins Dollies. Collins Hi-Speed Dollies came about to increase the safety and speed that a vehicle could be recovered. Prior to that, dollies were completely assembled underneath a vehicle after using a jack to raise it high enough. Though a great invention for their time and capabilities, these pan dollies were heavy and exposed the operator to roadside hazards for an extended period because of the time it took to assemble. Collins Hi-Speed Dollies improved upon this concept and changed the towing industry with a self-loading dolly in 1972. Their Hi-Speed name is partly due to quicker setup and tow times, since the dollies themselves were used to raise the vehicle.

Collins Hi-Speed Dollies came about to increase the safety and speed that a vehicle could be recovered. Prior to that, dollies were completely assembled underneath a vehicle after using a jack to raise it high enough. Though a great invention for their time and capabilities, these pan dollies were heavy and exposed the operator to roadside hazards for an extended period because of the time it took to assemble. Collins Hi-Speed Dollies improved upon this concept and changed the towing industry with a self-loading dolly in 1972. Their Hi-Speed name is partly due to quicker setup and tow times, since the dollies themselves were used to raise the vehicle. Because you don’t get to choose where or in what conditions the vehicle lies, it helps to have the proper equipment that works as hard as you do. Collins Dollies are built to handle inclement weather, rough road conditions, heavy loads and long-distance towing if required. Properly maintained, loaded and secured, Collins Hi-Speed Dollies can safely be used on highways, freeways and interstates to move the vehicle where you need to go. A single service truck with a wheel lift and Collins Dollies can do the work of multiple trucks, increasing profitability.

Because you don’t get to choose where or in what conditions the vehicle lies, it helps to have the proper equipment that works as hard as you do. Collins Dollies are built to handle inclement weather, rough road conditions, heavy loads and long-distance towing if required. Properly maintained, loaded and secured, Collins Hi-Speed Dollies can safely be used on highways, freeways and interstates to move the vehicle where you need to go. A single service truck with a wheel lift and Collins Dollies can do the work of multiple trucks, increasing profitability.

W

W TowMate started from very humble beginnings with the owner flagging down tow operators to show them his new invention, wireless tow lights. As far back as 1985, he made his way around the country doing this often stopping to sleep in his vehicle when he could afford no other option. Fast forward to today and nearly every tow parts supplier in North America, and many overseas, carry the TowMate line. Most readers of this magazine are probably familiar with that story and with the strides in innovation TowMate continues to make in terms of wireless tow lights. However, fewer are likely to be aware of just all TowMate offers today for each of the needs mentioned in the above paragraph. Every TowMate dealer has access to their full product offering too so take note on what you would like more information on after reading the rest of this and be sure to ask your local supplier.

TowMate started from very humble beginnings with the owner flagging down tow operators to show them his new invention, wireless tow lights. As far back as 1985, he made his way around the country doing this often stopping to sleep in his vehicle when he could afford no other option. Fast forward to today and nearly every tow parts supplier in North America, and many overseas, carry the TowMate line. Most readers of this magazine are probably familiar with that story and with the strides in innovation TowMate continues to make in terms of wireless tow lights. However, fewer are likely to be aware of just all TowMate offers today for each of the needs mentioned in the above paragraph. Every TowMate dealer has access to their full product offering too so take note on what you would like more information on after reading the rest of this and be sure to ask your local supplier. When it comes to lights on a service truck, the setup can range from ‘four-corner strobes’ to adding an overhead light bar or even a traffic arrow at the rear. There are no lights in the world that are as rich in functionality and simple to install than the Power-Link series made by TowMate. These lights can operate off of factory wiring (think, no more running wires from the front of the truck to the rear), and are completely programmable to operate as STT/markers/strobes/work lights/all of the above in some cases. Not to mention the fact that the Power-Link overhead light bars simply require power/ground to the bar and power/ground to the controller to operate. The same is true for the traffic control arrows in this series, which come in varying lengths and with a ‘split option’ as well. And, for the win, the best part is they are made in the USA and carry a lifetime warranty on electronics and LED’s.

When it comes to lights on a service truck, the setup can range from ‘four-corner strobes’ to adding an overhead light bar or even a traffic arrow at the rear. There are no lights in the world that are as rich in functionality and simple to install than the Power-Link series made by TowMate. These lights can operate off of factory wiring (think, no more running wires from the front of the truck to the rear), and are completely programmable to operate as STT/markers/strobes/work lights/all of the above in some cases. Not to mention the fact that the Power-Link overhead light bars simply require power/ground to the bar and power/ground to the controller to operate. The same is true for the traffic control arrows in this series, which come in varying lengths and with a ‘split option’ as well. And, for the win, the best part is they are made in the USA and carry a lifetime warranty on electronics and LED’s. “Okay, I’ve lit up my truck, but I need a way to begin warning motorists of my presence in advance of the truck, what have you got for that,” you ask? While there are many options for portable lighting systems and LED flares in the market, none exceed the brightness of the MO-PRO “move over LED flare.” With its 105LB pull magnetic base, four light patterns (red flare / red-blue strobe / amber-white strobe / solid white area light), along with a 16 hour run time on a single charge, the MO-PRO is the most versatile portable light we have ever seen. Built to a higher standard and including a hard-shell carrying case, you will not regret adding one to your service trucks repertoire. Want to add one more layer of safety for the roadside jobs? TowMate has developed a perimeter warning system, the ‘Safety Alert System,’ that alerts roadside workers when a vehicle has potentially crossed into their work area.

“Okay, I’ve lit up my truck, but I need a way to begin warning motorists of my presence in advance of the truck, what have you got for that,” you ask? While there are many options for portable lighting systems and LED flares in the market, none exceed the brightness of the MO-PRO “move over LED flare.” With its 105LB pull magnetic base, four light patterns (red flare / red-blue strobe / amber-white strobe / solid white area light), along with a 16 hour run time on a single charge, the MO-PRO is the most versatile portable light we have ever seen. Built to a higher standard and including a hard-shell carrying case, you will not regret adding one to your service trucks repertoire. Want to add one more layer of safety for the roadside jobs? TowMate has developed a perimeter warning system, the ‘Safety Alert System,’ that alerts roadside workers when a vehicle has potentially crossed into their work area. Aside from lighting and roadside

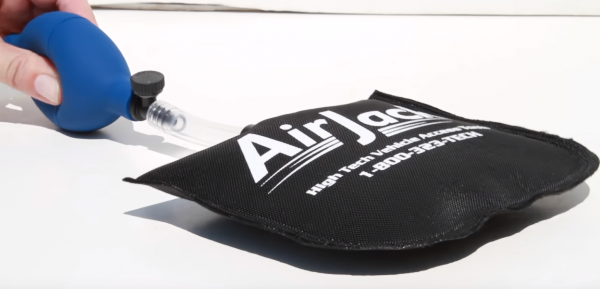

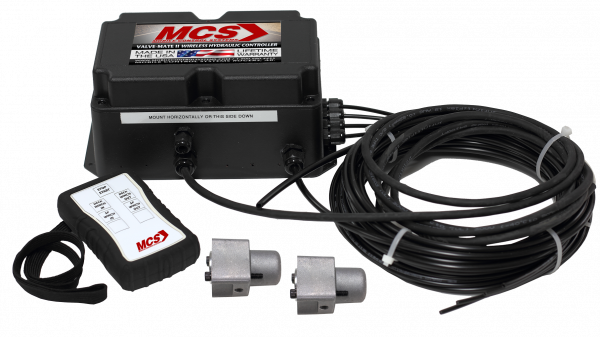

Aside from lighting and roadside  Finally, with the acquisition of Mobile Control Systems, TowMate now offers and manufactures a full range of radio remote solutions for winches, lifts, cranes, and more. The Valve-Mate series is, once again, one of the most simple-to-install remote valve operating systems in the world and comes at a highly competitive price. Manufactured right next door to TowMate’s main operations, held to the same quality standards, and carrying a lifetime warranty on electronic components, the Mobile Control Systems remote solutions should definitely be considered when making your next purchase.

Finally, with the acquisition of Mobile Control Systems, TowMate now offers and manufactures a full range of radio remote solutions for winches, lifts, cranes, and more. The Valve-Mate series is, once again, one of the most simple-to-install remote valve operating systems in the world and comes at a highly competitive price. Manufactured right next door to TowMate’s main operations, held to the same quality standards, and carrying a lifetime warranty on electronic components, the Mobile Control Systems remote solutions should definitely be considered when making your next purchase.

D

D The Service Truck is equipped with four rollup-door storage compartments for safe and easy curbside access totaling an amazing 80-cubic feet of usable space. The fenders are poly, so no more rust, and they are lighter, so you can carry more cargo weight without the risk of being overweight.

The Service Truck is equipped with four rollup-door storage compartments for safe and easy curbside access totaling an amazing 80-cubic feet of usable space. The fenders are poly, so no more rust, and they are lighter, so you can carry more cargo weight without the risk of being overweight. Our units have roll-up doors that do not swing out into the path of traffic, but rather roll up into the truck. This eliminates the possibility of passing vehicles catching an open storage compartment door and creating a traffic incident with the service truck endangering the life of the tower or customer.

Our units have roll-up doors that do not swing out into the path of traffic, but rather roll up into the truck. This eliminates the possibility of passing vehicles catching an open storage compartment door and creating a traffic incident with the service truck endangering the life of the tower or customer.

B

B

B

B