HINO TRUCKS INTRODUCES NEW MODELS AND CAB CONFIGURATIONS

Hino Trucks has been asking you for a few weeks now the simple question: What size are you? Well, now it’s time to answer that question. Hino has unified its entire lineup of trucks, including model names, to make it even easier for you to match the perfect Hino to you and your business’ needs. Hino is excited to announce their new ‘M Series’ Class 4/5 COE’s and new ‘L Series’ Class 6/7 Conventional trucks, which combined with Hino’s recently launched ‘XL Series’ Class 7/8 vehicles, creates a cohesive family of commercial trucks.

The badges are not the only updates either. Each vehicle now contains larger cab configurations, and a full suite of features adding safety, fresh designs, durability, flexibility and connectivity options, making it clear why Hino is the fastest growing medium-duty truck brand.

The new COE truck models carry Hino M4 and Hino M5 badging with the number in the naming scheme representing GVW class. For 2021MY, these trucks have been upgraded with an all-new grille design complete with optional LED headlights and HD 6-speed Aisin automatic transmission with gear hold feature. Available with the industry’s first OE fully integrated Lane Departure Warning System in this vehicle segment and then we get to the interior upgrades with a new shifter layout, steering wheel controls, an all-new gauge cluster including a 4.2” LCD multi-information display and driver’s seatbelt sensor.

The new Conventional line is represented by the Hino L6 and Hino L7 models boasting a bolder front fascia with optional LED headlights. The cab interior has been re-engineered with an automotive grade finish designed for commercial use and improved functionality, steering wheel controls, a large 7” LCD multi-information display, more storage and leg room. Hino also takes your safety very seriously, which is why there are now an array of safety systems available on the Hino L Series including Electronic Stability Control (ESC), Collision Mitigation System (CMS), Lane Departure Warning (LDW), Active Cruise Control (ACC) and driver’s seatbelt sensor. Adding even more functionality to your business are new wheelbase options and extended and crew cab configurations.

“Having extended and crew cab choices will help us better serve our customers’ operational needs and open-up new markets for our trucks” explained Glenn Ellis, SVP Customer Experience. “It’s impressive how accommodating and spacious both cabs are. Our engineering and design team really did an outstanding job with our new full line-up!” The 30” extended cab will have seating for 5 and the 44” crew cab will have full-size doors and seat 6 passengers and provide the comfort of rear zone A/C and heat.

The Hino XL Series also gets new advantages for 2021 model year including the extended cab and crew cab configurations and a snow plow package complete with an 18,000 lb. GVW front axle and front frame extensions. The Hino XL7 and XL8 will now come standard with a driver’s seatbelt sensor and available ACC building on the trucks’ ESC, CMS and LDW active safety solutions.

Hino Trucks dealers are now accepting orders for the new 2021 models. The extended and crew cab variants will be added in the Spring and the XL snow plow package in Summer timeframe.

Hino Trucks, a Toyota Group Company, manufactures, sells, and services a lineup of Class 4-8 commercial trucks in the United States. Hino Trucks is the premier heavy & medium duty nameplate in the United States with a product lineup that offers fully connected vehicles with low total cost of ownership, superior fuel economy, unmatched reliability and maneuverability and the most comprehensive bundle of standard features in the market. Headquartered in Novi, Michigan, Hino has a network of over 240 dealers nationwide committed to achieving excellence in the Ultimate Ownership Experience.

Learn more about Hino Trucks at http://www.hino.com or follow us on Facebook, Linkedin, Twitter and YouTube.

Jerr-Dan Promotes Heath Fassnacht to Director of Sales

Jerr-Dan Corporation, an Oshkosh Corporation company (NYSE:OSK) and single brand leader in the towing and recovery business, has promoted Heath Fassnacht to Director of Sales. He had been District Sales Manager for the southern region.

Fassnacht started his career in 1996 with Atlanta Wrecker and Carrier Sales, now known as Atlanta Wrecker Sales, a well-known Jerr-Dan distributor in the south. Following a progressive career with the company, he joined Jerr-Dan in 2015 as a national accounts manager before being named district sales manager.

“I’m humbled to have the opportunity to continue being a catalyst for Jerr-Dan’s growth in the towing and recovery equipment industry,” said Fassnacht. “I’ve been working in this business since graduating from college in 1996, and I’m proud to be representing the single brand leader in the industry.

“We have a great team in place across sales, operations, engineering and other key functions, and are poised to continue expanding into new markets, backed by the best distributor network in the country. I look forward to continue supporting our current customers and building relationships with prospective Jerr-Dan distributors.”

In his new role, Fassnacht’s primary responsibilities will include sales growth strategy, sales team management and expansion into new markets.

“We are incredibly fortunate to have someone with Heath’s background in the industry willing to accept this responsibility,” said Richard Del Campo, vice president and general manager of Jerr-Dan. “It is increasingly challenging to find senior leaders with track records like Heath’s who continue to push themselves and those around them. Jerr-Dan is proud to place our sales team alongside his leadership.”

For more information on Jerr-Dan products, visit www.jerrdan.com.

Don’t Let it Happen to You – Protect Your Trucks

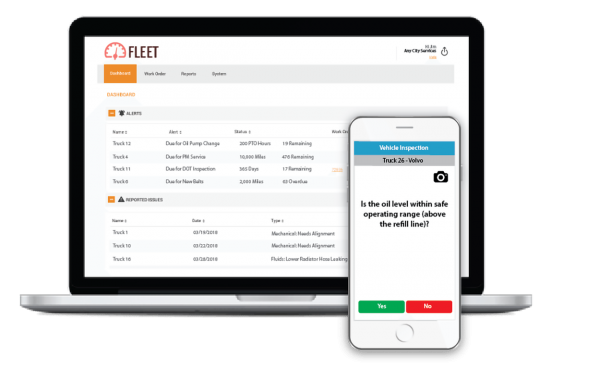

Its Monday morning, 8:21 am–it’s always Monday! The shop smells like metal and oil–burned oil. Somewhere, the all familiar drip-drip of leaking fluids reminds you of another problem yet to be fixed. The clipboard in your hands contains work orders and vehicle inspections, all illegible, torn, and smeared. A call from a driver says they have been rear ended in an accident. Wasn’t there a note about a broken taillight? When did it break? When was the last time the truck was inspected? Forms get ignored for being illegible. Inspections are delayed or insufficient from mismanaged schedules. Where are the inspections? They are at the bottom of a stack of smeared and illegible forms somewhere in a pile in the office. In short, your fleet maintenance has suffered a breakdown of key elements, and it’s gonna cost you–time, customers, and money! SureEcosystems Fleet helps to protect your trucks and assets with an easy-to-use, web-based maintenance software, keeping you aware of day-to-day vehicle operations.

TELL ME MORE

Fleet creates a direct line of communication between you and your drivers, eliminating paper forms, allowing you to stay on top of your fleet maintenance. The software will alert you immediately when any issue is reported, so it can be properly addressed. Fleet offers complete work-order management, so you can create and assign work orders, track current status staying on top of hours of labor, total cost, and downtime.

WOULDN’T IT BE NICE

Wouldn’t it be nice to have your drivers or technicians, who operate your vehicles, check out the vehicle and their tools prior to each shift? Obviously, we all hope our drivers do a walk around inspection, and we hope that they leave the shop or start their day with the tools required to perform their jobs. Using sureEcosystem Fleet, you can accomplish this and much more, as well as have a daily record and accountability. When a driver begins their shift, they perform an inspection completely customized by you. The site provides a template to work from with many questions already available for you to use in building your inspection. You can add other questions as well. In addition to checking the oil or the tire pressure, your drivers can also check to make sure that specific items are on the vehicle (or in the vehicle) that are needed to perform their work like insurance cards, for example. Deficiencies can be tracked, drivers can restock vehicles, alerts can be set, or work orders generated into your maintenance tracking system. “Work Orders” can be set as well based on your preferences tied to the specific questions you use in your company. Many other types of inspections can also be performed including vehicle end-of-shift check in and appearance inspections. All these inspections are used in building reports that let you know what’s going on with your fleet and your business. It also lets you know which employees are performing the work you would like them to do in accordance with company policy.

TRACK THE MAINTENANCE PERFORMED ON YOUR VEHICLES

SureEcosystem also tracks all the maintenance performed on your vehicles. Whether it is in your own shop or outside shops. The site allows you to keep track of the costs of maintaining each vehicle individually. Work being performed on vehicles is tracked using work orders in sureEcosystem that can be assigned to internal technicians, external shops, or others.

SureEcosystem also tracks all the maintenance performed on your vehicles. Whether it is in your own shop or outside shops. The site allows you to keep track of the costs of maintaining each vehicle individually. Work being performed on vehicles is tracked using work orders in sureEcosystem that can be assigned to internal technicians, external shops, or others.

Customizable thresholds allow you to maintain, inspect, and replace vehicle components on a regular schedule that you define. This may mean that you want to perform preventative maintenance on different schedules for different vehicles or to check brakes, tires, or other items at defined intervals. SureEcosystem even lets you track maintenance thresholds for the ancillary equipment attached to your truck or specific vocational bodies. Equipment such as tankers, tool bodies, ambulances, tow trucks, tree service equipment, and specialized vehicle components for many other industries.

WAIT, THERE ARE MORE COOL FEATURES!

There is a way to create alerts and proactively address preventive maintenance and service requirements. That way is through “Vehicle Records,” a feature that allows one to manage permits, licensing, registration, and other time-sensitive documents.

ACCIDENTS HAPPEN

Drivers can report accidents directly from the mobile app. The app ensures that all the proper information is collected, including photos and audio recordings. SureEcosystem also utilizes “Driver Qualification,” a feature that saves time managing and organizing your drivers with features including groups, attached documents, reminders on actionable items, and intelligent pre-populated driver information.

OH, ALMOST FORGOT ABOUT “WORK ORDERS”

This feature assigns and manages tasks performed on your vehicles. “Work Orders” track useful data points including multiple service types, technician, parts required, costs, labor, and total downtime.

So, whether you are dealing with proactive vehicle maintenance, driver and work order management, or accident prevention and management, sureEcosystem Fleet keeps you aware of day-to-day vehicle operations and empowers you to effectively manage your staff and their daily work orders with this user-friendly, web-based maintenance software. The best way to see what sureEcosystem Fleet can do for your business is to simply start a free trial. All you do is go to sureEcosystem.com/fleet, click the free trial tab, and you’re up and running! You can also take the time to do a demo with one of our specialists and learn more about how to use all these tools in your specific business operations. Everyday does not have to be a Monday!

FACING THE CHALLENGES OF TOMORROW

Facing the Challenges of Tomorrow- “Hell,” you say, “I’m happy if I can get through today’s challenges and keep my customers happy.” I hear that kind of comment every week from towing and VSF owners, and yet many are light years ahead of their competitors. “Why are they ahead?” you ask. Because they have learned the important rules of business: “Pay Attention to your Customer Needs and Follow the Money.” To achieve the simple goal of understanding your customers historical needs and your company’s financial situation, many have invested in effective management software. If you haven’t yet licensed towing management software (TMS), then you should consider it a priority.

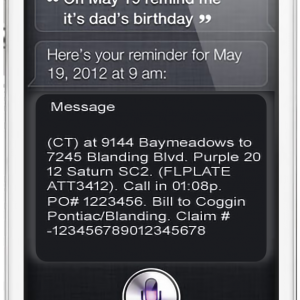

The onslaught of technology is changing everyone’s future, and the towing, recovery, and vehicle storage industry is no exception. Our recovery vehicles have become more sophisticated, but technology is also making them easier and safer to use. Yet it’s the unseen advancements in software that is really changing the way in which we operate, and without doubt, it is a major part of our future! What used to be a hard division of duties between the office and tow truck is now becoming a blur due to web-based TMS programs and the mobile app.

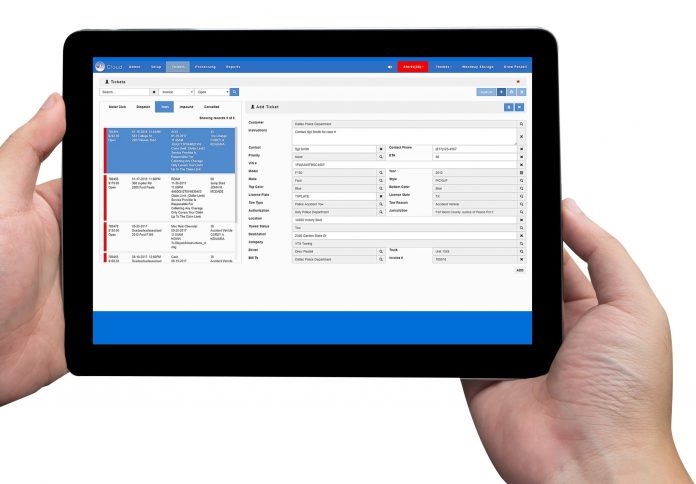

The benefits of CLOUD computing and the use of mobile apps or remote browser-based tablet access are not only beneficial to small companies but offer efficiency and cost reduction benefits to any business regardless of size. Connectivity to your CLOUD-based TMS program via the Internet, can be from ANY DEVICE, ANYTIME, ANYWHERE; this would include a desktop PC, a laptop, Android or iPad tablet, or a smart phone.

The benefits of CLOUD computing and the use of mobile apps or remote browser-based tablet access are not only beneficial to small companies but offer efficiency and cost reduction benefits to any business regardless of size. Connectivity to your CLOUD-based TMS program via the Internet, can be from ANY DEVICE, ANYTIME, ANYWHERE; this would include a desktop PC, a laptop, Android or iPad tablet, or a smart phone.

As the end user of any product or service, it is not necessary to understand the in-depth nuances of how it works, only that it does what you need.

Investing in management software should achieve three primary goals:

- Simplify the operation of your business by creating standard operating procedures (SOP), which provide common sense, step-by-step actions.

- SOP will provide statistical reporting, track your customers historical needs, follow the money, and track your cash flow, allowing you to make better, more informed business decisions.

- Informed business decisions will ultimately reduce the number of people required to effectively operate your business without impairing customer satisfaction and thereby improving your profit margin.

The benefits of CLOUD-based TMS – If you are a small owner-operated company, it makes business sense to be able to manage your entire operation from the cab of your tow truck. VTS Systems offers both web-based CLOUD and PC/server based TMS programs. Why offer both? If your business location does not enjoy reliable high-speed Internet, then a PC/server TMS program may be better choice, as it does not require constant Internet access to provide full-time operability. Even in the largest US cities, there are areas zoned for industrial use that do not enjoy reliable high-speed Internet. Moreover, whatever Internet problems city towing companies face, their country cousins usually operate in a more challenging environment. Although hardwired or fiber-optic broadband services are the most efficient, cellular and wireless data often provide a viable fallback alternative. We suggest that you talk to a knowledgeable expert, not just a product salesperson to define your Internet options.

If you are considering new TMS software, invest time in defining your needs and researching various options. There are TMS software vendors who specialize in towing, whereas others provide full-service packaging which include:

- Unlimited towing,

- Variable driver commission/bonuses,

- Accounting A/R, invoices, and statements,

- State compliant Storage Lot Management and vehicle processing,

- Integrated, multi-state DMV owner and lienholder access and retrieval,

- Automated, on time notification/lien letter processing via electronic certified mail, return receipt requested,

- Integrated Public Auctions/Sales Processing and Title Documentation.

Considered by many to be a leader in TMS, VTS Systems has served the towing and vehicle storage facility industry for more than twenty years, and nobody does storage lot management better than we do, PERIOD. We offer full-service, comprehensive basic TMS packaging with optional feature/expansion modules. Included in the monthly licensing fee, VTS Systems provides full product support and software upgrades along with end user training. Since no two companies’ needs are exactly alike, we suggest you only license what you need!

Considered by many to be a leader in TMS, VTS Systems has served the towing and vehicle storage facility industry for more than twenty years, and nobody does storage lot management better than we do, PERIOD. We offer full-service, comprehensive basic TMS packaging with optional feature/expansion modules. Included in the monthly licensing fee, VTS Systems provides full product support and software upgrades along with end user training. Since no two companies’ needs are exactly alike, we suggest you only license what you need!

Should you have questions regarding the information in this article, please contact VTS Systems at 877.374.7225, Ext. 2 and ask to speak to Lisa Perez. Lisa Perez is a state-licensed tow-truck operator with more than twenty years of experience in operating and managing state licensed storage facilities.

“Follow the Leader” is an Invitation to Succeed –

What is “Follow the Leader?” For Beacon, it’s an invitation to towing and roadside assistance companies to step ahead of their competitors and take advantage of the number one dispatch software on the market. For businesses that require dispatch software, it’s a reminder that finding the right system takes work. There are lots of companies popping out of the woodwork, and it can be difficult to sort through the multitude of advertisements and flashy slogans.

That’s why Beacon keeps it simple. In August of 2019, Beacon Software began the “Follow the Leader” campaign in order to connect with towers and showcase 19 strong years in the towing and roadside assistance industry.

It’s no wonder roadside assistance professionals around the world depend on Beacon to provide easy-to-use tools that help them efficiently dispatch their drivers and manage their businesses.

Beacon Goes the Distance

![]() Customer expectations change with shifting technology and industry standards, which is why Beacon Software employees go the distance to keep their customers informed about product updates and training opportunities. When you’re on the road and you run into a question, you need an answer fast. In addition to regular email updates, Beacon Software delivers the friendliest support staff in the industry.

Customer expectations change with shifting technology and industry standards, which is why Beacon Software employees go the distance to keep their customers informed about product updates and training opportunities. When you’re on the road and you run into a question, you need an answer fast. In addition to regular email updates, Beacon Software delivers the friendliest support staff in the industry.

What makes Beacon Software different? Beacon was designed for towing and roadside professionals by industry veterans. Rudy Smith is the CEO of Beacon Software, and co-owner of Rudy Smith Towing and Recovery. This New Orleans-based towing operation is celebrating its 100th year in business. He cites the importance of using tow management software, “Without accountability, it’s difficult to discern the best ways to improve your business and offer more efficient roadside assistance,” says Smith. “Things like map view, instant access to driver locations and payment processing changed the game completely.” Having spent years on the road himself, Smith recognizes how critical a robust software solution is to his business.

Companies consistently recognize Beacon for their flagship product, Dispatch Anywhere, the program that took the towing and roadside assistance industry into the future, but Beacon’s suite of software offers a solution for everyone. Most recently, Beacon Software introduced the GPS Map View feature to Dispatch Anywhere’s sister product, TowMagic. Now, companies of all sizes can track drivers and get ETAs for faster, more efficient dispatching.

First in Show

Beacon Software is known for its firsts, but most people don’t know just how many features it introduced to the towing and roadside assistance industry. The following are just the top ten features that Beacon made possible with Dispatch Anywhere.

- 1st Cloud Based

- 1st Digital Dispatch

- 1st Computer Aided Dispatch

- 1st GPS Integration

- 1st Smart Phone Manager/Driver App

- 1st in Data Security

- 1st Multi-Division Management System

- 1st Mobile Credit Card Integration

- 1st Automated Motor Club Billing

- 1st Drag and Drop Dispatch

The best part about being first in the industry is that Beacon had the most time to develop and modernize its software. Today, Beacon Software looks a lot different than it did in the beginning–same great ideas with cleaner, modernized applications.

Your Next Employee of the Year

If you ask any Beacon customer, they’ll tell you one of their favorite employees is their Dispatch Anywhere system. That’s because owning a software that saves time and enforces accountability is priceless. Your software can never replace your dedicated, hardworking drivers and dispatchers. Rather, your software exists to support your team and help you connect with motor clubs, your staff and your customers.

One of the most important things a software company can do is listen to its customers. Beacon Software takes customer feedback and uses it to improve their platform. Most recently, Dispatch Anywhere updated to include automatic job import for IAA and Copart, enhanced its job tracking history and introduced more benefits for Square credit card users. Additionally, Dispatch Anywhere provides the following, integral features.

- A/R Accounting– As well as the ability to export to Quickbooks™.

- Smart Assign-Lightning fast recommendations to minimize time finding the best driver for the call.

- Track Assets– Know where your drivers and vehicles are in relation to their jobs on a map.

- Autocomplete– Minimize data entry with address autosuggest and pricing templates for quick and accurate call entry.

- Anywhere Mobile– Dispatchers are not chained to a desk. They can be mobile and manage every call.

- Dispatch Motor Club Jobs– Assign jobs that are sent from motor clubs.

- Continuous FREE Training- Never get left in the dark on new features. Faster ramp up for new employees.

Live Weekly Training with Matt

President of Beacon Software, Todd Althouse, realized that, as Beacon evolved, it would need to develop modern ways to communicate with its customers. “One of our proudest achievements is our ability to connect with our customers. Matt’s regular training and demo updates allow our customers to communicate directly with and learn even more about their software investment,” says Althouse.

Keeping your employees fully trained and up-to-date on new features is one of the best ways to stay ahead of your competition. In order to better share updates and tutorials with Beacon Customers, Training and Support Manager, Matt Tortorici, hosts demos, training sessions, and informational assemblies live on YouTube every Friday at 1 pm EST.

Taking the Leap into Towing and Roadside Management Software

Making the switch to use dispatch software can be daunting, especially because the towing and roadside assistance industry is built on the back of tried and true methods. No one knows these methods better than Ronnie Smith, co-owner of Beacon Software and Rudy Smith Towing and Recovery. Smith assisted in the recovery management efforts of one of the worst natural disasters to date, Hurricane Katrina. “We could have never managed 17 towing companies, hundreds of tow trucks and recovered tens of thousands of boats and vehicles after Katrina if we had not developed Dispatch Anywhere. It’s just a necessity and has made life so much easier,” says Smith. “No one likes change, but once you make the switch to Dispatch Anywhere, you will wonder why you didn’t years ago. It just makes your operation run so much more efficiently, relieves stress, and saves money.”

Auto Data Direct

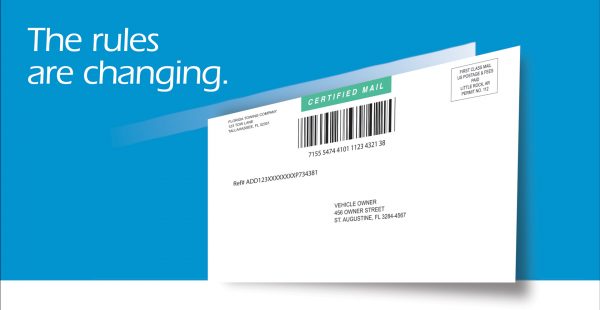

The 2019 Legislative sessions in Florida and Georgia brought substantial change to tow and wrecker operators in those states. But Auto Data Direct has the industry covered when it comes to meeting new state regulations!

Florida Change Requires Third Party for Notification

In Florida, the notification process is changing. Effective January 1, 2020, all towing companies, title companies who process tow liens, mechanic shops, and body shops are required to send their notification letters for sale or lien through an approved third-party service. Additionally, the third party will be required to set up and maintain a publicly available website that allows owners, registrants, lienholders, and insurance companies to search for notices. If your company is an Auto Data Direct (ADD) customer and already processes letters through its DirectPost-Office (DPO) product, your business is all set. ADD has provided a high-quality, third-party notification system recognized by the Florida Department of Highway Safety and Motor Vehicles (DHSMV) since 2003!

Overhaul of Georgia’s Tow Statute

Georgia’s new law, which became effective September 1, 2019, resulted in a major overhaul to the towing statute. Tow companies must send the notification letter developed by the Council of Magistrate Court Judges by certified mail or hand delivery. There are also changes in the timeframe during which letters must be sent. Georgia tow and wrecker operators currently using ADD’s DPO service are ahead of the game! ADD modifies its system and letters to meet new requirements as they are implemented by the state, and its Georgia letter tools are ready and available to the industry.

Another big benefit for Georgia tow/wrecker companies utilizing ADD’s suite of tools comes with the recognition of its DMV123 owner/lienholder records and ADD as the department’s authorized vendor for motor vehicle records. For details on Georgia’s statute changes and information on ADD’s designation as an agent for records, visit dor.georgia.gov/abandoned-vehicles.

ADD’s Suite of Tools Is a Tow Operator’s Best Friend!

For those who aren’t familiar with ADD’s DirectPost-Office (DPO) certified mail product, it was launched in 2003 to provide Florida towing companies an easier way to send notification letters to owners, lienholders and insurers by creating certified mail and inserting the letters into the USPS mail stream electronically. Since then, DPO has expanded its letter services for towing operators in Texas, Alabama, Connecticut, Indiana, Georgia, Mississippi, North Dakota, and Tennessee. DPO is a tow operator’s best friend. It combines letter creation with state record searches to complete forms and send certified letters through the United States Postal Service without an aggravating trip to the post office! As notification requirements change, as has occurred in Florida and Georgia, ADD modifies it letters and processes specific to a state to meet the needs of its customers.

For those who aren’t familiar with ADD’s DirectPost-Office (DPO) certified mail product, it was launched in 2003 to provide Florida towing companies an easier way to send notification letters to owners, lienholders and insurers by creating certified mail and inserting the letters into the USPS mail stream electronically. Since then, DPO has expanded its letter services for towing operators in Texas, Alabama, Connecticut, Indiana, Georgia, Mississippi, North Dakota, and Tennessee. DPO is a tow operator’s best friend. It combines letter creation with state record searches to complete forms and send certified letters through the United States Postal Service without an aggravating trip to the post office! As notification requirements change, as has occurred in Florida and Georgia, ADD modifies it letters and processes specific to a state to meet the needs of its customers.

As a compliment to DPO, ADD’s multi-state real-time motor vehicle records save time, money, and frustration when it comes to getting notification letters out in a timely manner. Coined DMV123, ADD’s most sought after service allows its customers who qualify under the Drivers Privacy Protection Act (DPPA) to search through its secure system using a VIN and immediately retrieve the most current record available from a jurisdiction, in real time. As already mentioned, Georgia has designated ADD’s records as the official agent for records.

Using ADD’s National Title Pointer helps narrow down the search when the state of origin isn’t easily identified. The Title Pointer uses data available in the National Motor Vehicle Title Information System (NMVTIS) to find the most recent state of title. Once identified, ADD’s customers can search the real-time database if that state is available or send a good faith letter directly from their ADD account to the appropriate jurisdiction.

Once a vehicle is towed, and the record is accessed, DPO allows the data to be merged into the appropriate form, saving keystrokes and ensuring accuracy. Once the letter is electronically submitted to the mail stream, DPO allows for tracking the certified letter every step of the way providing details on when the letter(s) was received, or if it was undeliverable. The DPO archive provided in an ADD account gives tow operators documented proof that notification requirements were followed if a question arises about whether the appropriate actions were taken to find the owner/lienholder prior to holding an auction.

For tow/wrecker operators who need to report junk or salvage vehicles to NMVTIS, ADD provides a solution from the same web-based account. Any entity that deals in more than five junk and salvage vehicles per year must provide specific vehicle information to the national database on at least a monthly basis. NMVTIS reporting applies to any vehicle a company parts out or crushes, or any vehicle for which a salvage certificate, a certificate of destruction, or similar document is obtained. If a business has the right to sell or re-title, rebuild, restore or crush the vehicle, and it is a junk or salvage vehicle under the federal definition, it must be reported to NMVTIS.

ADD’s NMVTIS upload tools are designed to help businesses fulfill the reporting requirement quickly and easily. Two account types are available to suit any size business or upload volume. Full-service accounts include individual vehicle entry, batch vehicle entry using a spreadsheet and business-to-business processing which can be arranged with the customer’s IT staff, all for a low per-report fee. Basic-service accounts include no-cost individual entry and emailed confirmation receipts.

Learn More About ADD and Get Started Today!

ADD provides innovative tools every step of the way for tow operators focused on ensuring their business processes are efficient, accurate, and cost-effective, all backed by the friendliest, most knowledgeable customer service in the industry.

If your company already has an ADD account but is not using DPO, just click the orange DirectPost-Office icon in My Apps to begin processing your notification letters. If you are new to ADD, click on the sign-up button on its home page to take advantage of these valuable business tools.

For more information on scheduled training classes and webinars, or to speak with one of our friendly and knowledgeable customer service representatives, call 850-877- 8804 or email info@add123.com.

ITRHFM Adds 28 Names to Its Wall of the Fallen

The International Towing & Recovery Hall of Fame and Museum added twenty-eight new names to the Wall of the Fallen during its recent annual ceremony honoring towing and road service operators who have died in the line of service.

The names include those from previous years as the details of fatalities become known. In all, the Wall of the Fallen now has over 450 names of men and women who have lost their lives while serving the motoring public in the towing and road service industry. (See below for complete list of towing operator names added in 2019.)

The Wall of the Fallen ceremony seeks to honor towing operators whose lives were cut short and the Survivor Fund provides a one-time gift to the families. Survivors’ families also receive a Certificate of Honor at the ceremony.

“It is with great sadness that we find ourselves in a position that requires the Wall of the Fallen,” stated Jeffrey Godwin, Wall of the Fallen and Survivor Fund co-chairman. “Despite the tragedy represented, we do find comfort in honoring our fallen operators and in serving their families in their time of loss.”

The annual ceremony also aims to boost motorists’ awareness of Move Over laws in effect in all 50 states that require drivers to move over one lane and/or slow down when approaching an emergency vehicle.

Annually, the motoring public’s failure to slow down or move over, in addition to drunken or negligent driving, unnecessarily claims many towers’ lives.

2019 Wall of the Fallen

(in alphabetical order)

| Honoree Name | State | Year |

| Phillip F. Amsden | IN | 2010 |

| Patric Noel Barrio | TX | 2019 |

| Michael Charles Buffington | MS | 2019 |

| Patrick Cisneros | NM | 2019 |

| Garold L. Cline | WV | 2018 |

| Jerry E. Davenport | AR | 2018 |

| Ernest Linden Dean | KY | 1945 |

| Steven E. Eldridge | NC | 2019 |

| Erwin Mendoza Geremillo | CA | 2019 |

| Trevor A. Haas | IL | 2018 |

| Richard Arturo Hernandez | CA | 1999 |

| Jesse Hettmann | WI | 2019 |

| Keith Holt, Sr. | TX | 2019 |

| Elwood Allan Humphries | VA | 2018 |

| Clarence C. Jones, Jr. | PA | 1963 |

| Charles C. McGough | TX | 2018 |

| Juan Manuel Morga | CA | 2018 |

| James Robert Morris | CA | 2019 |

| Terrell Dean Pack | TX | 2019 |

| Willie J. Passmore, Jr. | NE | 2011 |

| Edgar Arthur Pilon | Canada | 1954 |

| Kevin B. Raasch | KS | 2019 |

| Clarence Hugh Souther, Jr. | GA | 1962 |

| Benny G. Sprinkle | NC | 2019 |

| John L. Stewart | MO | 2018 |

| Paul Wayne Taylor, Jr | TX | 2018 |

| Jason Stuart Throne | IN | 2019 |

| Michael R. White | OK | 2018 |

About ITRHFM

The International Towing and Recovery Hall of Fame and Museum, located in Chattanooga, TN, houses an array of displays and exhibits showcasing the history of towing and recovery. The rotating collection includes early equipment by Manley, Holmes, Vulcan, and Weaver. The Hall of Fame honors individuals who have significantly advanced the industry. The Museum includes a theater, a library, and a gift shop selling souvenirs related to the towing industry. On the outside grounds is the Wall of the Fallen memorial, dedicated to towers who died in the line of service. The ITRHFM Survivor Fund assists the families of the men and women that have made the ultimate sacrifice in the line of service by providing a uniform financial gift at the time of their loss. ITRHFM is a non-profit 501(c)(3) organization and accepts donations for its programs and operations from individuals, corporations and groups.

Learn more at www.towingmuseum.com

TRAA Joins Coalition to Halt Four Bills with “Burdensome” Unfunded Mandates

The coalition sent a letter on Sept. 16 to Sen. Roger Wicker (R-Mississippi), chairman, and Sen. Maria Cantwell (D-Washington), ranking member, of the Committee on Commerce, Science and Transportation; and Rep. Peter DeFazio (D-Oregon), chairman, and Rep. Sam Graves, R-Missouri, ranking member, of the Committee on Transportation and Infrastructure.

The four bills are:

• The Stop Underrides Act (H.R. 1511/S. 665): which would require the installation of front, side and rear underride guards on all trailers with a gross vehicle weight rating (GVWR) that exceeds 10,000 pounds and all single-unit trucks with a GVWR greater than 10,000 pounds and a carriage that is more than 22 inches above the ground.

• The Cullum Owings Large Truck Safe Operating Speed Act of 2019 (S. 2033): which would mandate commercial motor vehicles (CMVs) over 26,000 pounds to be equipped with speed limiters set to 65 mph.

• The Safe Roads Act (H.R. 3773): which would require new CMVs to be equipped with and utilize an automatic emergency braking (AEB) system.

• The INSURANCE Act (H.R. 3781): which would increase the minimum liability coverage for motor carriers from $750,000 to over $4.9 million. This increase would apply to all businesses transporting property, not just long-haul trucking operations.

In addition to TRAA, the other members of the coalition are: the Agricultural Retailers Association; Agriculture Transportation Coalition; American Dairy Coalition; American Farm Bureau Federation; American Pipeline Contractors Association; American Pyrotechnics Association; Associated Equipment Distributors; Associated Oregon Loggers; Association of Professional Towers of Ohio; Corn Refiners Association; Distribution Contractors Association; Mid-West Truckers Association; National Asphalt Pavement Association; National Association of Small Trucking Companies; National Cotton Council; National Cotton Ginners’ Association; National Council of Farmer Cooperatives; National Grain and Feed Association; National Hay Association; National Ready Mixed Concrete Association; National Stone, Sand and Gravel Association; National Utility Contractors Association; National Wildfire Suppression Association; NFIB; North American Millers’ Association; Owner-Operator Independent Drivers Association; Police Towers of America; Power and Communications Contractors Association; Precast/Prestressed Concrete Institute; and United States Cattlemen’s Association.

Dynamic’s New Service Truck – A Solid Towing Industry Solution!

Dynamic Towing Equipment and Manufacturing has another solid towing solution to the industry! Dynamic worked with motor clubs and towers across the country to design a service truck specifically tailored to satisfying the customer’s needs. We spoke directly with those who already owned our trucks and even spoke to our potential customers who are considering them. Listening to what they said, we then turned their feedback into features that empower them to work more efficiently and quickly resulting in higher revenues and lower costs of operation. Specifically, we found that an effective service truck needs plenty of storage, additional recovery capabilities, and increased safety, so here is what we did to design a service truck that delivers what our customers need:

WE CREATED PLENTY OF STRATEGIC STORAGE SPACE.

The Service Truck is equipped with four rollup-door storage compartments for safe and easy curbside access totaling an amazing 80-cubic feet of usable space. The fenders are poly, so no more rust, and they are lighter, so you can carry more cargo weight without the risk of being overweight. These huge compartments can be delivered with an optional adjustable rack system for vehicle batteries and can provide safe stowing of up to 36 batteries in large boxes able to hold enough batteries to cover most vehicles on the road. The boxes have adjustable shelves with tie-downs, so the batteries are always secured while in motion. In addition, both sides of the Service Truck have wide toolboxes and another large storage compartment on the deck for a total of seven compartments. Accompanying deck space measuring 54” x 85” allows for plenty of space for dollies, go jacks, and additional storage options.

The Service Truck is equipped with four rollup-door storage compartments for safe and easy curbside access totaling an amazing 80-cubic feet of usable space. The fenders are poly, so no more rust, and they are lighter, so you can carry more cargo weight without the risk of being overweight. These huge compartments can be delivered with an optional adjustable rack system for vehicle batteries and can provide safe stowing of up to 36 batteries in large boxes able to hold enough batteries to cover most vehicles on the road. The boxes have adjustable shelves with tie-downs, so the batteries are always secured while in motion. In addition, both sides of the Service Truck have wide toolboxes and another large storage compartment on the deck for a total of seven compartments. Accompanying deck space measuring 54” x 85” allows for plenty of space for dollies, go jacks, and additional storage options.

Also, tool-box compartments are installed to accommodate all normal roadside assistance tools and equipment as well as an air compressor with front and rear quick disconnects to allow the tech complete flexibility to service vehicles in all positions. Even with the additional storage boxes, the center deck is still open for additional storage of equipment, when equipped with out stealth unit.

WE INCREASED OUR TRUCK’S RECOVERY CAPABILITIES ELMINATING THE NEED FOR MULTIPLE VEHICLES.

We originally started with a 4000-lb. lift, then went up to a 5000-lb. under lift. We decided to add a 5000-lb. wheel lift with a recovery boom and an 8000-lb. Ramsey winch. A front push bumper is also available with an optional winch. We did this because after speaking to our customers, we found that they were wanting one vehicle to do as much as possible, so now you can do everything from a battery boost to a battery replacement to a tow or all the way up to a recovery with one vehicle. The service technician can test the disabled vehicle’s battery and electrical system to get the vehicle running under its own power. If necessary, the tech can install a new battery in the vehicle at the breakdown site. However, as in many cases, the battery is not the cause of the breakdown. After eliminating all the things a Service truck can do to assist the stranded customer, all you must do now is hook up the car.

We originally started with a 4000-lb. lift, then went up to a 5000-lb. under lift. We decided to add a 5000-lb. wheel lift with a recovery boom and an 8000-lb. Ramsey winch. A front push bumper is also available with an optional winch. We did this because after speaking to our customers, we found that they were wanting one vehicle to do as much as possible, so now you can do everything from a battery boost to a battery replacement to a tow or all the way up to a recovery with one vehicle. The service technician can test the disabled vehicle’s battery and electrical system to get the vehicle running under its own power. If necessary, the tech can install a new battery in the vehicle at the breakdown site. However, as in many cases, the battery is not the cause of the breakdown. After eliminating all the things a Service truck can do to assist the stranded customer, all you must do now is hook up the car.

Consequently, because of the increased capabilities of our Service truck, we don’t have to dispatch a tow vehicle to complete the service call and tow the customer to their repair facility; our Dynamic service truck can handle the job. The customer does not have to wait for another vehicle to arrive, and you as an owner do not have to send multiple vehicles to the same breakdown location. We improve operational efficiency saving on fuel, vehicle wear and tear, and overhead while still providing the same high level of service our customers have come to expect.

WE IMPROVED SAFETY THROUGH OUR STORAGE-COMPARTMENT DOOR DESIGN.

Our units have roll-up doors that do not swing out into the path of traffic, but rather roll up into the truck. This eliminates the possibility of passing vehicles catching an open storage compartment door and creating a traffic incident with the service truck endangering the life of the tower or customer.

Now even though utility and safety for our customers are premium values to us, we didn’t sacrifice aesthetics–we wanted our trucks to look good. As a result, the sleek body style makes this service truck a definite eye-catcher on the road and within the industry.

Dynamic’s new service truck is truly a solid towing solution to the needs of the industry with its practical and spacious storage compartments and enhanced recovery capabilities, all while providing more protection for the lives of towers. It’s a Dynamic solution!

FEATURE HIGHLIGHTS:

- 4-year warranty

- Designed to us a 60CA OR 84CA chassis with an additional 24-in. tunnel box

- All poly-fender construction

- 4 large roll-up door compartments with shelving

- 3 fold-down door compartments with plenty of additional storage

- Optional adjustable batter racking system

- Optional 5000-lb. wheel lifts with or without winch and recovery boom.

- Open deck space to store dollies, go jacks, cones, and fuel and water tanks.

“Best Tools” You Can Depend On

Best Tools is a family-owned and operated business which started over 35 years ago handcrafting lockout tools in the USA striving to have the best quality lockout gear in the industry. From day one, all Best Tools lockout-tool equipment was, and still is, 100% made in the USA along with using raw materials right here in America. Every lockout tool we make is produced from scratch right here in Northwest Arkansas. Because quality means durability, “our lockout tools take a lickin’ and keep on pickin’.” In addition to support businesses here, we are committed to learning from and growing with the ever-changing needs of all the industries we serve.

In the last 5 years, Best Tools decided to make a jump to carefully rebrand and re-market the image and expand the product line outside of what we manufacture. We started hitting the streets getting the name out there and by request from a variety of customers, Best Tools grew. After diligently picking only the elite manufactures out in the market, we wanted to grow with only the best from wireless tow lights, emergency lighting, rigging and recovery equipment, tie-down straps, skates, transport and trucking products, wire rope, winches, and industrial radio wireless remote controls, suspension enhancement products to much, much more. The list will always be evolving to serve the customer in the best way. Best Tools offers a full domestic line with an imported option to satisfy every customer throughout all the different industries we serve. To this day, some of the dealers and relationships we have made with customers throughout the variety of industries we serve are still with us growing together.

Also, in the last five years, we invested in a van that would hit the ground fully stocked with all kinds of products calling on industries from towing companies, mechanic shops, dealerships, body shops, construction companies, trucking companies, police and fire stations to municipalities. If we feel you could use Best Tools products, we will stop and see you, now that we have two vans hitting the streets. Talking to customers face-to-face and establishing a relationship, we have modified and improved our lockout tools and have designed new products to help the towing industry. Just to name a few items, our Silver Snatcher lockout tool (our version of the Axle chain and Steering Wheel strap) has been a huge hit in the market.

Also, in the last five years, we invested in a van that would hit the ground fully stocked with all kinds of products calling on industries from towing companies, mechanic shops, dealerships, body shops, construction companies, trucking companies, police and fire stations to municipalities. If we feel you could use Best Tools products, we will stop and see you, now that we have two vans hitting the streets. Talking to customers face-to-face and establishing a relationship, we have modified and improved our lockout tools and have designed new products to help the towing industry. Just to name a few items, our Silver Snatcher lockout tool (our version of the Axle chain and Steering Wheel strap) has been a huge hit in the market.

Now for us, it’s not just about success in the past making tools that that match the variety of needs, it’s also about being relevant to today’s challenges, so there is always something new we try to bring to the industry every year. In the last year, so far, we have developed a hand full of newer products by high demand requests from our customers: One is the “Mega Bag,” a bigger air wedge with a strong insert to get through the toughest doors in the market. Another is the ” Average Joe” which is a smaller version of the very poplar standard magic wand for those who have a shorter reach and need something more versatile. The “Extra Long Magic Wand” is great for big trucks with a 70″ reach. Also new is the “Slim-Picker” which is great for mustangs and convertibles with a slightly smaller diameter than the magic wands.

So, you can not only get dependable, quality lockout gear from Best Tools, but now you can also get top notch rigging and recovery equipment, transport and trucking straps and restraints, emergency lighting and strobe light heads, truck accessories and work lighting, safety gear, wireless tow lights and wireless control systems, skates, winches, wire-rope and synthetic slings to much more. All of this is from a company committed to providing cutting-edge technologies inspired by direct customer feedback. Best Tools has always been a “grass root” business focusing on reaching out to the customer in a personal way. Remember, “When People Rely on You – You Can Depend on Us!”

So, you can not only get dependable, quality lockout gear from Best Tools, but now you can also get top notch rigging and recovery equipment, transport and trucking straps and restraints, emergency lighting and strobe light heads, truck accessories and work lighting, safety gear, wireless tow lights and wireless control systems, skates, winches, wire-rope and synthetic slings to much more. All of this is from a company committed to providing cutting-edge technologies inspired by direct customer feedback. Best Tools has always been a “grass root” business focusing on reaching out to the customer in a personal way. Remember, “When People Rely on You – You Can Depend on Us!”

You can check out their products through your local dealer, check them out online www.besttoolsusa.com or give us a call 800-541-8568. Maybe we will even see you a trade show!

Ian Wallace Hero Nomination

During August 2018, while in the course of his shift as a heavy-vehicle recovery driver, 34 yr. old, Ian Wallace, who works for R. D. Avery Recovery of Romsey, Hampshire, was despatched at approximately 11:00 am to attend and recover a broken-down, 44-ton articulated vehicle.

He arrived at the scene at the junction of the A34 and A 303 to find the vehicle totally blocking the exit road. He met the Man service technician who he knew as John and who was already on-scene and attending the initial breakdown of the vehicle with his technical service van; however, the breakdown was a major component failure, and it was necessary to have the vehicle towed to the workshops for repair. While waiting for the heavy-recovery vehicle to arrive, John started making the necessary preparations that are required to make the vehicle ready for towing. He had removed the drive shaft and had lifted it into his van.

When he arrived, Ian manoeuvred his recovery vehicle into position to enable him to lift the front of the truck which was ready to tow. He connected the necessary airlines in from the recovery vehicle to the casualty vehicle’s braking system. Because of the dangerous position they were in with trucks and cars passing only inches away at speeds up to 70 mph, John said, “Let’s get out of here! Don’t worry about lights on the trailer; I will follow you back to the workshops with my emergency lights on.”

They got underway and proceeded along the A34 southbound. Because of the extreme length of the recovery vehicle towing the articulated vehicle, Ian decided to pull into the service truck area at Sutton Scotney anyway to put on the lights. On arrival at the services, Ian got out and walked to the rear of the vehicle with his light board and cable over where John was parked in his van with the engine running and all the emergency lights on. Without looking up, Ian called out to John, “Where do you want me to put this in the lot when we get to your garage?” There was no reply. He looked up and noticed John was slumped over the wheel. He shouted out, “JOHN!“ There was no reply; so concerned, he ran up to the van not knowing what was wrong. His first thoughts were, “Was the handbrake on?” “Was it in gear?” He opened the driver’s door and turned the engine off and placed the vehicle in gear.

He raised John’s head off the steering wheel as he took his last gasp of air before he stopped breathing! He shouted to the driver of the truck he was towing, “CALL AN AMBULANCE! HE’S GONE!” The driver immediately did that, but at that time, did not come over to see what was happening.

Ian pulled John out of his van onto the tarmac. (He was not the smallest of people.) He laid him on his back and began CPR. It was something that just came to Ian after seeing it on TV. John was turning greyer and greyer as several onlookers had gathered. The emergency services were now on the speaker phone talking him through the CPR procedure. This went on for seven and a half minutes until the ambulance arrived shortly followed by the air ambulance. They got the defibrillator and shocked him. They asked Ian to carry on with the compressions until the next shock. They shocked again and again, and then John resuscitated after 10 minutes since Ian had started CPR.

John was transported to the hospital and placed into an induced coma for the next 10 days. Ian kept in touch with John’s company to check on his progress. It was not looking good, but then on day 11, Ian received a phone call saying that John had come out of the coma and was responding well–even sitting up, eating, and drinking! Ian was shocked and relieved that John was going to be okay.

Ian had occasion to tow another vehicle into the same Man dealership a few weeks later only to be informed that John was back at work! Ian was in disbelief. Wow! It seemed much too early, but there John was! Ian went into the workshops to see him, and the first thing John said was ”Ian, you broke my ribs!!“ John was laughing at the time, so after they both embraced and shook each other’s hands. Ian replied, ” No Problem, Any Time!”

The only effect John has from his ordeal is a loss of a few weeks’ memory which proves to Ian that miracles can and do happen! At the time of the incident, Ian had never had any first aid training and could not believe that he saved a man’s life! He has since taken first aid training and fully believes everyone should do a course in basic First Aid. Here is a hero for you—Ian Wallace.

John Copeland Background Info:

He was born in the UK in 1946 and has been in the towing and recovery industry for 58 years along with his wife, Aileen, and his sons, Matthew and Graham. He established one of the largest towing and recovery operations in south of England, operating over 100 vehicles out of 5 locations.

He is currently involved in organizing and presenting numerous recovery and rescue demonstrations to the industry, fire and police authorities and the general public. He is strongly committed to raising the public awareness of “Slow Down Move Over” and the dangers that the recovery operators face at the roadside. He is also active in several trade councils working on raising of standards of training, safety, and public perception of the towing and recovery industry.

Concerning honors: in 2019, he was inducted into the Towing and Recovery Hall of Fame in Chattanooga. In 2013, He received a Fellowship from the Institute of Vehicle Recovery for services to the Recovery Training programs. Also, in 2013, he received the UK Towing and Recovery Industry Lifetime Achievement Award for outstanding services to the recovery industry. In 2007, he received an honorary lifetime membership to the Association of Vehicle Recovery Operators, for services rendered to the association.

Tow Professional– “A story will soon follow on this remarkable man, John Copeland.”

PROTECT YOURSELF WITH SITUATIONAL AWARENESS!

In the past few weeks, a tow driver in Texas was shot and killed by two men at an apartment complex in Houston. Another driver attempting to perform a private-party impound (PPI) and aggressively defending his “catch” was shot but survived. Another driver was shot while being robbed.

There are several subjects that immediately come to mind when I hear of an unfortunate chain of incidents like this. First and foremost, I think of ways we can avoid putting ourselves into scenarios where we might be in danger. Danger is common in the repossession and PPI areas of the industry, but it can also crop up during much more routine tows. The other issue is very complex – carrying a weapon. You need to know your legal rights to do so or not, to know how to handle yourself in potential high-risk situations, and to know that carrying a weapon can land you in jail or be used to legally defend yourself.

We often work alone in our industry. You have communication via a radio, phone, or satellite system, but none of those methods can truly help you if you are confronted with violence or an otherwise threatening situation. In high-risk areas or on high-risk tows, perhaps you can use the buddy system and have another driver work in an “overwatch” position able to respond to your location easily or at least call for help. I performed PPI towing in San Antonio and Denton, Texas, and PPIs and repossessions in the greater Philadelphia area. We ran in packs of two or three trucks or rode with two people in a single unit, consequently and thankfully, we avoided trouble. There’s a safe way to do an unsafe job, but you must plan and keep your head on a swivel.

Tow Professional magazine isn’t a forum for gun rights or the Second Amendment, so I’m not about to get on my soapbox about what we should or could do out there. I know from my background in law enforcement and as a licensed concealed/open carrier via my state concealed- carry license and my federal Law Enforcement Officer’s Safety Act (LEOSA) carry-permit, there are still huge restrictions, even with the latter’s 50-state reciprocity. There are many places you already can’t carry a weapon, like government buildings, hospitals, and any business with proper signage prohibiting weapons. With that said, and I’m sure some will argue, there is absolutely no restriction for carrying a weapon in a commercial vehicle, unless prohibited by laws in your state or city. As long as the law allows it and your company allows it, and you’re properly licensed and trained, you may carry. Please think again about the restrictions, and the notion that merely showing your weapon as a matter of threat or intimidation is a felony in most jurisdictions. To cut a complex idea to simpler terms, you can’t pull your weapon unless confronted with an equal threat.

There have been many arguments about the “weapons in commercial vehicles” subject, and after years of debate, I figured out where this notion came from. According to 18 USC 926a, when transporting weapons or ammunition as cargo, weapons must not be transported with ammunition, and said weapons or ammunition must not be accessible from the passenger compartment. The most important aspect of that directive are the words “as cargo.” Transporting a load of shotguns to a sporting goods store isn’t the same as carrying your personal weapon. This 18 USC reference is supported in FMCSA 49 CFR.

One last thing, other than keeping your head on a swivel – if you’re remotely thinking about carrying a weapon, please understand that just because your uncle was in Vietnam, and he taught you to shoot a .22 rifle into a tree when you were 12, that doesn’t count as training and experience. Training and experience are far more valuable than a weapon itself – get some decent marksmanship safety training and spend significant time at the range before considering carrying a weapon. Most people who attempt to defend themselves without proper training and familiarity or brandish a weapon due to ego and lack of experience and knowledge, end up dying or seriously injured or in jail. Check your ego, get some training, and be careful.

Technology and the Towing Industry – The TowTrax Solution

Since we are talking about the motor clubs and dispatch systems, let me point out a few things I’ve discovered as I deal with many service providers. I have contacted no less than 25 service providers, and most of them are fighting the same problems:

- Pricing – This industry is very competitive as motor clubs fight to survive. As they fight for their share of the market, they must lower their tow fee as low as possible to win business. As I look at some of the pricing, I can see why they have trouble getting tow companies to take calls. I talked to a tow company last week, and he told me that he was the 32nd company the service provider called to get someone to run the call. I was asked by several providers not to put their names on the tow for fear that the tow company would not take the call if they knew who it was. We can make the call look like a TowTrax call and not display the service provider.

- Remote Areas – One motor club asked me if I could cover their remote areas. I asked them what they considered a remote area; they told me Milwaukee. That surprised me since Milwaukee is a large city. When TowTrax looked at 50-mile radius in Milwaukee, we found 72 tow companies. We registered over 30 in the Milwaukee area, so if any service provider needs help in that area, let us know.

- Change – The service providers have been operating for years doing what they do today. They are 20 years behind in technology, and they know they must change but there is a fear factor. When I first developed TowTrax, one of my partners told me there is no way you will get these service providers to change the way they do business because the change would be too hard compared to what they do today. It’s interesting that the service provider wants to change, but no one wants to be first. They can’t afford to disrupt the poor service they offer today.

- Poor ETA’s – Some service providers admitted that their ETA’s were over an hour on average. A girl in the office was telling me she waited over two hours when she broke down and called her service provider. She was in the Dallas area which makes it worse.

- Their Tow Network – The service providers go to tow shows and try and register tow companies to service their calls. There are over 70,000 tow companies nationwide, but it’s the same 15,000 tow companies that go to all the shows. These are usually large tow companies that use the tow shows to see what is new in the industry. These companies don’t use many service providers for their main line of business. They do police rotation, body shops, and other sources as their main source of business. As a result, the motor clubs struggle with their towing network.

- Multiple Contracts – When service providers sign contracts with tow companies, they may offer one company a price for light or medium duty with a per-mile fee after 5 miles. Then they go to a second provider and offer that tow company different prices for the same area. The service provider ends up managing multiple contracts with multiple tow companies. Then, when they get in a remote area, the service provider will call anyone to take the call. Even if there is no contract between the service provider and the tow company.

- Fees and Credit Cards – When a service provider can’t find a tow company to run a call, they are forced to pay double the fee to get a company to run the call. When the tow company takes the call, they ask for a credit card to make sure they get paid.

- No Resources – I talk to several providers that want to use TowTrax but have no technical staff available to work with us. They will continue to lose money and provide a poor service until they make time to upgrade their technology.

The new problem for many service providers is the new companies that are entering the industry. They have plenty of money and tech staffs that can that can develop whatever is needed to support their business. They advertise on their websites that they are here to put the old service providers out of business. When you have money and resources at your disposal, you can do whatever is needed to win the business.

I know for a fact that several major customers that are currently with a service provider have gone to them for some changes, but the service provider ignores them for reasons I don’t understand. It will not be long that new technology will start to take customers away from some service providers.

A message to the service provider: you can’t continue to do busines

s the way you do today. A lot of companies have developed something that connects with the consumer. Remember you can’t service a call without the tow truck. At some point in time, you will have to improve your technology if you want to compete in the business. TowTrax makes it simple and provides a service like no other. The change in your business is made easy with TowTrax.

Preliminary Injunctive Relief Regarding the Massachusetts State Police (“MSP”) Request For Response (“RFR”)

The Towing and Recovery Association of America, Inc.® (TRAA) has joined the Statewide Towing Association, Inc. of Massachusetts, and several Massachusetts towing companies, in filing a request in Federal District Court seeking preliminary injunctive relief regarding the Massachusetts State Police (“MSP”) Request For Response #SP20-TOW-X81 (“RFR”). The MSP RFR is a bid request for companies to provide towing, recovery, and roadside services for the MSP relating to law enforcement actions, accidents, roadway clearance, and disabled motorist services and would replace the current Tow Service Agreement (“TSA”).

The RFR includes several areas of concern from tower safety, tow company appeal rights, onerous equipment requirements, and contradictory educational requirements for tow operators. TRAA has signed on as a party to protect not only our own interests with the National Driver Certification Program® but also our many member towing companies and certified towing professionals within the state.

For more information, visit Statewide Towing Association, Inc. of Massachusetts

TomTom Telematics Officially Renamed Webfleet Solutions

From today, the company previously known as TomTom Telematics is operating under the new name Webfleet Solutions. Webfleet Solutions will continue to provide exactly the same market-leading products and services TomTom Telematics was known for, including WEBFLEET, NEXTFLEET, LINK devices and the range of PRO Driver Terminals.

While no longer a business unit of the TomTom Group, having been acquired by Bridgestone Europe in April 2019, Webfleet Solutions will remain a key business partner of TomTom and continue to utilize its award-winning “Traffic and Maps” in its services.

“20 years ago, we launched our WEBFLEET fleet management solution from our original office in Leipzig, Germany”, said Thomas Schmidt, CEO and Managing Director, Webfleet Solutions. “We were forerunners in using cloud and internet technologies to help fleets and companies with commercially used trucks, vans and cars to boost productivity, increase safety and sustainability, enhance customer satisfaction, and increase the overall efficiency of their fleet operations.”

“Today, we serve more than 50,000 customers with vehicles driving in 100 countries. As Webfleet Solutions, we will go further than just providing telematics solutions. Bridgestone gives us the perfect platform from which to do so, supporting us to create a wider scope of services for more customers across the world. With us, Bridgestone EMEA now manages 1.2 million mobility and fleet management subscriptions.”

MORE ON WEBFLEET SOLUTIONS

Webfleet Solutions, known as TomTom Telematics until October 1st 2019, is one of the world’s leading telematics solution providers, dedicated to fleet management, vehicle telematics and connected car services. Its main Software-as-a-Service solution WEBFLEET is used by businesses of all sizes to improve vehicle performance, save fuel, support drivers, and increase overall fleet efficiency. In addition, Webfleet Solutions provides services for the insurance, rental and leasing industries, car importers and companies that address the needs of businesses as well as consumers.

Webfleet Solutions has over 50,000 customers worldwide and services drivers in more than 100 countries, giving them the industry’s strongest local support network and widest range of sector-specific third-party applications and integrations. Our customers benefit every day from the high standards of confidentiality, integrity, and availability of our ISO/IEC 27001:2013 certified service, re-audited in November 2018.

Webfleet Solutions was formerly known as TomTom Telematics and was part of the TomTom group until 1st of April 2019 when it was acquired by Bridgestone Europe NV/SA (“Bridgestone”), a subsidiary of Bridgestone Corporation, the world’s largest tire and rubber company. Bridgestone operates in 38 countries across the EMEA region, with some of Europe’s most advanced factories, world-beating technology and leading R&D investments. For further information, please visit webfleet.com. Follow us on Twitter @WebfleetNews.

For more information about Bridgestone in EMEA, please visit www.bridgestone.eu and Bridgestone newsroom.