Speedbinders add efficiency, ergonomic advancement, and longevity to load securement and tie-down applications. We asked Joe Spelman, assistant product manager at The Crosby Group, how they do it.

Trucking professionals are leveraging the advantages of the Speedbinders Torque Drive product line that has recently been added to the portfolio offered by The Crosby Group, a leading global manufacturer of lifting, rigging, and load securement hardware.

US-based Speedbinders, a designer and manufacturer of pioneering load binders for heavy-duty load securement, was acquired by The Crosby Group this spring. The drill-operated Speedbinders not only provide faster tie-down and release times for drivers but also improve ergonomics and reduce strain injuries.

The product is targeted at anyone who operates, services, and maintains trucks and trailers. A broad range of professionals in equipment rental, manufacturing, steel, haulage, recovery, and logging have already leveraged its benefits—and The Crosby Group will widen utilization much further.

Solutions include the torque drive load binders, which use a portable power drill to secure loads, eliminating the need for repetitive, manual operations common with lever and ratchet binders. The product is available in three sizes:

• 5/16”-3/8”: working load limit (WLL) = 6,600 lb. (for 5/16” G70 chain)

• 3/8”-1/2“: WLL = 9,200 lb. (for 3/8” G70 chain)

• 1/2”-5/8”: WLL = 13,000 lb. (for 1/2” G70 chain)

Joe Spelman, assistant product manager at The Crosby Group, said: “The Torque Drive technology enhances worker safety and improves productivity for drivers, it is a winning combination! The reasons to choose a Speedbinder over a regular binder are many and include the fact that they’re quicker and easier to use; they save time and money; and strain injuries are dramatically reduced. Speedbinders provide additional opportunities for our valued channel partners, and together, we are bringing this innovation to end users worldwide.”

User Guide

You must own / operate a drill to use Speedbinders, but there are some other features that you should be aware of before putting the product to use:

• Reaction bar: ensure that the handle is firmly against the deck or load. The handle is not a traditional ratchet handle; it is a reaction bar that is loaded with approx. 50 lb. of force. This helps keep the chain tension when driving over bumps, but it is important that the angle of the handle to the deck / load is low to ensure that good contact is retained. The handle is offset to one side to help ensure a low angle. If the handle cannot rest against the deck, it may be flipped to rest against the load instead.

• Tightening sequence: with the increased tension achieved with the Speedbinder, it is important that the binders are tied down in sequence, tightening the slack first and then pulling to correct tension.

• Drill operation: the drill will give better rotational torque over an impact’s hitting torque allowing optimal final tension. Ensure that you hold the drill with both hands to counter-act the natural twist of the drill.

Using Speedbinders on your trucks

Commercial truck operators need to make informed decisions about buying and maintaining equipment, while monitoring industry best practices and new technologies. Many of these operators already utilize Crosby shackles, hooks, chains, and other products, while smaller-scale customers that use trucks and farming equipment might be more familiar with the Speedbinder brand itself.

Spelman explained: “We are excited to strengthen and expand the strong community of Speedbinders users. It was important to us that Steve Helline, founder of Speedbinders, continued to work with us after the acquisition to best support this critical customer base.”

Helline responded: “It has been an incredible journey to see this business from concept to significant adoption and now a partnership with a world leader in load securement. I can’t think of a better steward of my business going forward and I look forward to supporting the continued adoption of Speedbinders in the market.”

The Crosby Group has already moved manufacturing operations from Ohio into its facility in Longview, Texas. Regular training sessions are delivered to existing dealers, focusing on the product’s key benefits, starting with safety. Users report that worker compensation claims have been significantly reduced since implementing the product, and their most experience drivers have extended their careers due to the elimination of repetitive ratcheting motion.

Operated with a drill

The Crosby Group advises use of specific Milwaukee and DeWalt drills, but Spelman stressed that a high quality 18-20 volt, high-torque drill is ideal for best operation. These drills allow tie-down time reductions by up to three times, resulting in less fuel burned, less maintenance, and further time and money savings. Anybody, regardless of strength, can achieve higher tension than using a traditional binder. This higher tension is achieved by 24:1 gear ratio and continuous torque with equal pull on the chain, resulting in tighter tie-downs, less movement of loads, and reduced risk of binders loosening in transit.

One user said: “I have driven that load more than 700 miles, and I have not had to tighten a single binder down—not a single binder was loose the entire trip. I am completely sold on these binders and will be getting four more to make sure I have enough for all the future loads I will be pulling using my chains and Speedbinders.”

Speedbinders are also suited to use in confined spaces because there is no need to ensure there is enough space for a handle to move. This is particularly useful when working in the middle of steel coils, over equipment, or flat against the deck, which cannot be achieved using traditional ratchet binders. Other advantages include tamper resistance, as a tool is required to loosen loads; and longer life, largely because a sealed gearbox keeps dust, sleet, salt brine, etc. out.

Overall, more and more drivers are switching to Speedbinders to add efficiency, ergonomic advancement, and longevity to their load securement and tie-down applications.

About The Crosby Group

The Crosby Group is a global leader in the innovation, manufacturing and distribution of products and services used to make lifting and load securement safer and more efficient, with premier brands such as Crosby, Gunnebo Industries, Crosby Straightpoint, Crosby BlokCam, Acco, McKissick, Crosby Feubo, Trawlex, Lebus, and CrosbyIP.

With global engineering, manufacturing, distribution and operations, the company provides a broad range of products and solutions for the most demanding applications with uncompromising quality that exceed industry standards. www.thecrosbygroup.com

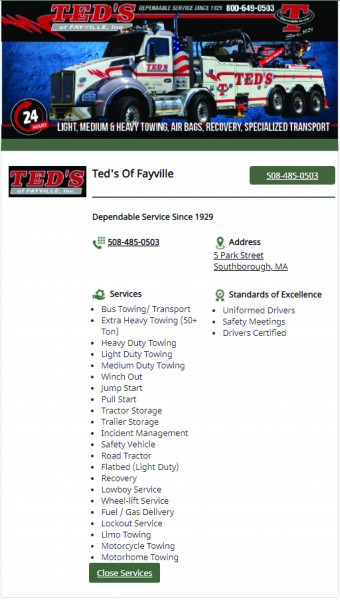

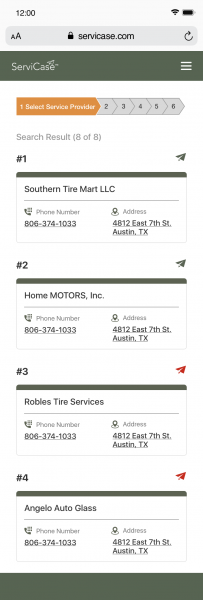

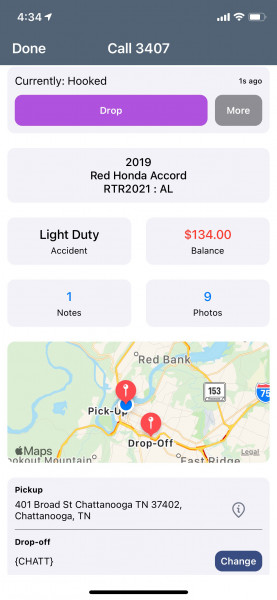

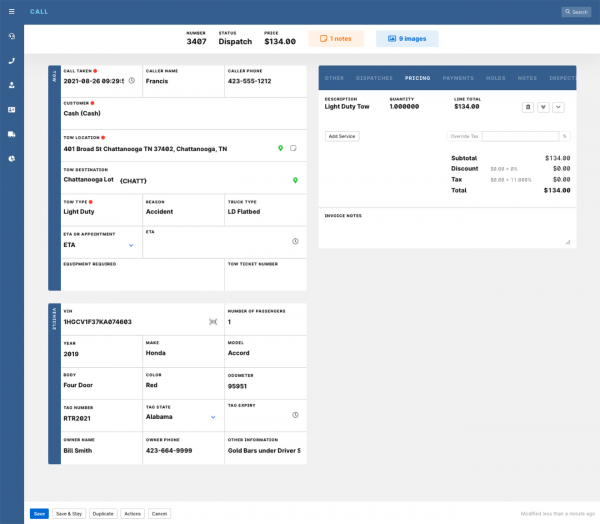

When your company is listed in ServiCase, you become a part of one of the most sophisticated networks available for roadside breakdowns. As more and more carriers adopt ServiCase as their breakdown platform, your business is exposed to fleets looking for the services you offer.

When your company is listed in ServiCase, you become a part of one of the most sophisticated networks available for roadside breakdowns. As more and more carriers adopt ServiCase as their breakdown platform, your business is exposed to fleets looking for the services you offer. The ServiCase breakdown management software is exceptional in that it can connect carriers and fleets directly to service providers through many of the commercially available dispatch software platforms including Beacon, FullBay, InTow, TOPS, Towbook and Omadi, and more than a dozen others.

The ServiCase breakdown management software is exceptional in that it can connect carriers and fleets directly to service providers through many of the commercially available dispatch software platforms including Beacon, FullBay, InTow, TOPS, Towbook and Omadi, and more than a dozen others.

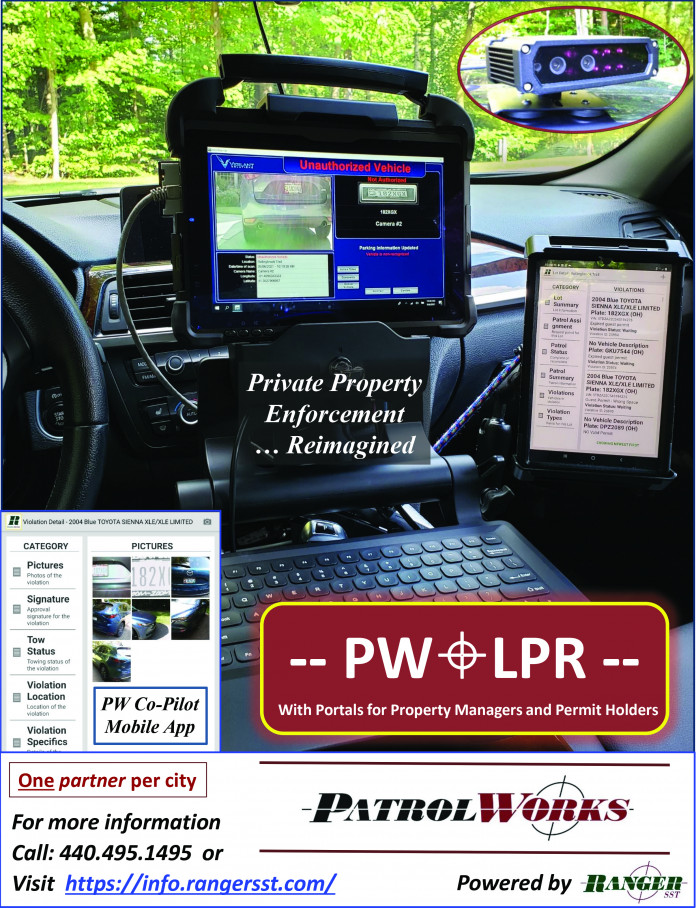

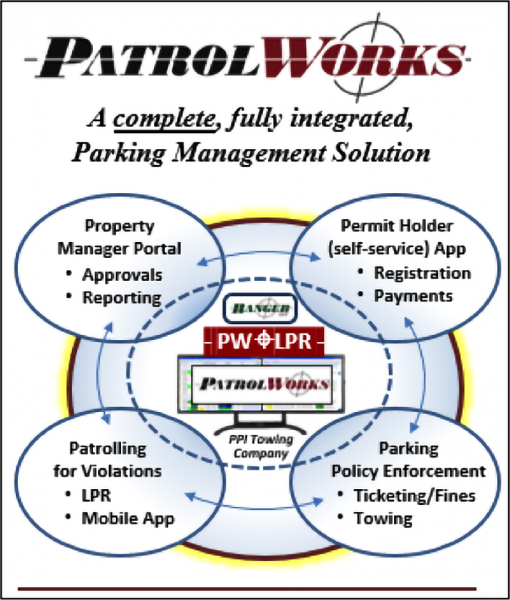

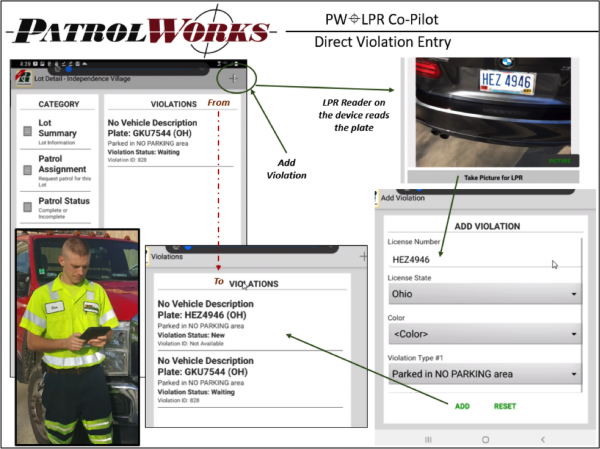

Q. But Permit Holders won’t pay the tickets

Q. But Permit Holders won’t pay the tickets

A. Guilty, but of course it is complicated. The camera systems are impressive (night and day) but are not inexpensive.

A. Guilty, but of course it is complicated. The camera systems are impressive (night and day) but are not inexpensive.

T

T Checkout.

Checkout.

The Life Saver (P/N: TM-LS) has changed form from its original design of a traffic cone with strobes mounted to it and housing a battery internally. It is now a self-contained unit that is universal to any traffic cone and features two LED strobes, lithium battery, and over 24 hours of runtime. This allows the user to continue to store cones by stacking them as well as move it from truck to truck with ease. The system itself is designed to be a quick deploy solution to get traffic moving over by placing it on the lead cone in advance of your work site. The standard model comes with two red and blue LED strobes that are sure to catch motorists’ attention. The light is not considered truck lighting and is not intended for use in motion and as a result has been widely accepted for use in such scenarios. However, other color options are available.

The Life Saver (P/N: TM-LS) has changed form from its original design of a traffic cone with strobes mounted to it and housing a battery internally. It is now a self-contained unit that is universal to any traffic cone and features two LED strobes, lithium battery, and over 24 hours of runtime. This allows the user to continue to store cones by stacking them as well as move it from truck to truck with ease. The system itself is designed to be a quick deploy solution to get traffic moving over by placing it on the lead cone in advance of your work site. The standard model comes with two red and blue LED strobes that are sure to catch motorists’ attention. The light is not considered truck lighting and is not intended for use in motion and as a result has been widely accepted for use in such scenarios. However, other color options are available.