The days when towing companies could run operations with a pad a pencil are a thing of the past. The demands of the industry are changing rapidly, and without adequate computer systems to manage those, companies can and will fall behind. With digital dispatching and complex reporting requirements coming from all sides, towing companies need sophisticated systems to handle these increasing demands to compete in this ever-changing landscape.

The days when towing companies could run operations with a pad a pencil are a thing of the past. The demands of the industry are changing rapidly, and without adequate computer systems to manage those, companies can and will fall behind. With digital dispatching and complex reporting requirements coming from all sides, towing companies need sophisticated systems to handle these increasing demands to compete in this ever-changing landscape.

In this world of interconnected devices and systems, towing companies have been forced to follow suit. Motor clubs, municipalities, law enforcement, and even the person on the street want to be able to request a tow from whatever kind of device they are using without having to pick up a phone and make a call. Law Enforcement wants to be able to send a tow request that is entered by the officer in the squad car. Motor clubs want to able to dispatch to a tower through their digital dispatching product. The person on the street wants to able to click on a link and request a tow without having to call all over the place to find a company willing to do the work. And then after the work is assigned, all the previously mentioned customers want to able to see a status of the driver’s progress to know when the driver will arrive.

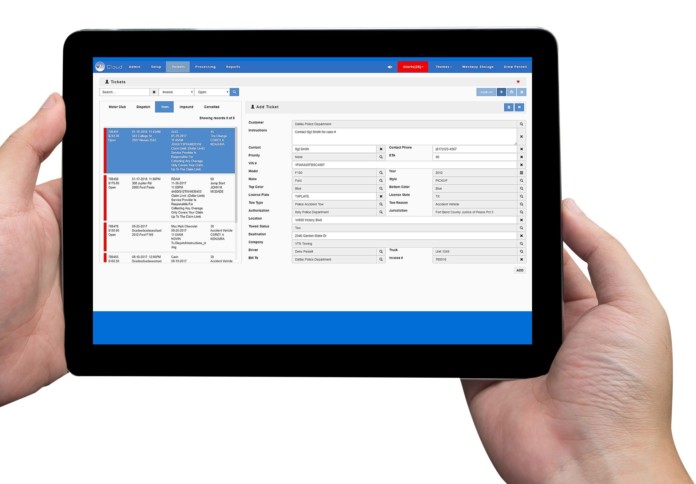

Companies large and small use software to run their towing operations. Large companies understand the necessity of integrated systems, but small companies can take advantage of all of the same features with the same impressive results. The web-based tools that are available to the towing industry in today’s world are better and more connected that ever. Even a small company that used to be only concerned with keeping records and invoicing can utilize the same digital tools that until recently were only available to large companies with large systems budgets. Quality computer systems already provide a retrievable history, can verify invoicing and manage receivables. But the real benefits are in the new features and the doors that it can open for your company, and the new business opportunities they present. While it does take time to input data and to learn how to use a system, in the end a business is able to offer a better product, get paid for all the work that is provided, and convey a more professional image to their customers.

Included in this article are some features of our TOPS® towing management systems which help to illustrate how software can be used to help you manage your business and to take advantage of these new and increasingly important technologies. These features help our customers streamline their overall business process, save time on daily tasks and offer a better and more professional product to their customers.

Municipality and Law Enforcement Towing

Municipality and Law Enforcement Towing

Towing on behalf of a municipality or a law enforcement organization can be a profitable part of a towing business. City and police contracts usually are signed and in place for several years and can amount to significant revenue. In addition, being associated with city and police contracts lends a certain amount of respectability to a company’s reputation.

As cities and law enforcement agencies continue the move towards modernization of their systems, they are demanding that towing companies do the same. The days of receiving telephone calls from police dispatch offices or receiving faxes to pick up abandoned vehicles are quickly becoming a memory. They want integrated systems that receive calls directly from their officers in the field, and from their dispatchers or CAD systems. They want GPS devices in the contractors’ trucks to allow for automatically dispatching to the closest truck. They want 20 minute ETAs with GPS-based accountability. They want paperless tow sheets, and real-time integrations with their records systems. If companies want to be in the law enforcement towing business, they are being required to have systems that support these technologies. Many of these contracts are awarded and then implemented in weeks and not months, and the computer systems’ provider must be prepared to integrate and assimilate information and processes quickly and without mistake. Cities take the health and safety of their citizens and law enforcement officers seriously, and the demands – and payoffs – can be high.

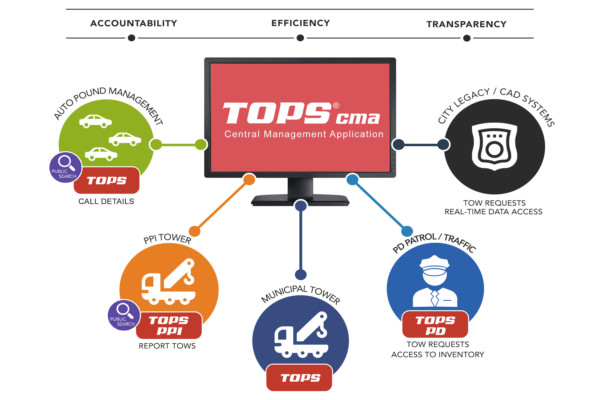

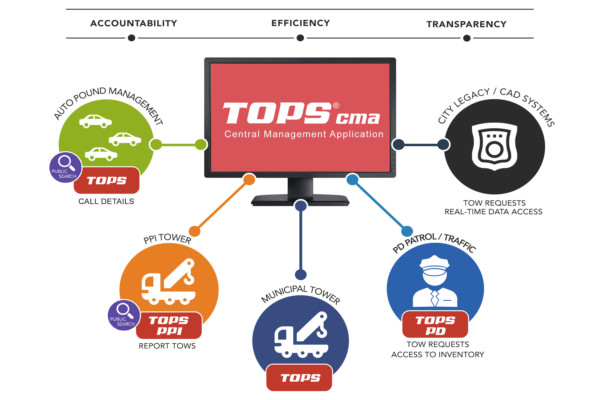

The TOPS® suite of municipal products includes several tools which cater to managing Dispatch, Towing management and Impound management with full transparency between all parties. The heart of the system is our TOPS CMA. TOPS CMA manages the creation and distribution of tow requests out to the contracted tow operators. The tow operators themselves can manage the towing and impounding of these requests using our TOPS impound software, with each driver able to use the TOPS Driver mobile application. As the towing and impound data is entered into the towers’ TOPS impound software, it is reflected back in real-time into the TOPS CMA for oversight and review by the municipality or law enforcement. The TOPS PPI system allows municipalities to monitor Private-Property Impound and Repossession firms as they enter non-consent tows. The TOPS PD system is a web-enabled search and reporting tool that allows 911 and 311 centers access to city summary impound data without granting them access to other systems. The TOPS Public Search tool allows the public to search across all City, county, private and PPI lots to find their vehicle if it has been towed.

This model of full transparency is what sets the TOPS suite of municipal applications apart from the rest. The next time you are fighting for local contracts, remember that these tools are available to law enforcement, to the city and to you – the local tow operator – to use in a 3rd party management role.

Motor Club Towing

Whether a towing company’s primary business is motor club calls or they simply use motor club calls to keep their trucks busy between account and police calls, motor club business can be a valuable asset to a towing company. In addition to traditional motor club operations, many automobile insurance companies now include motor club emergency service as part of their value-added services. Like it or not motor clubs are here to stay, and as a revenue stream they shouldn’t be ignored.

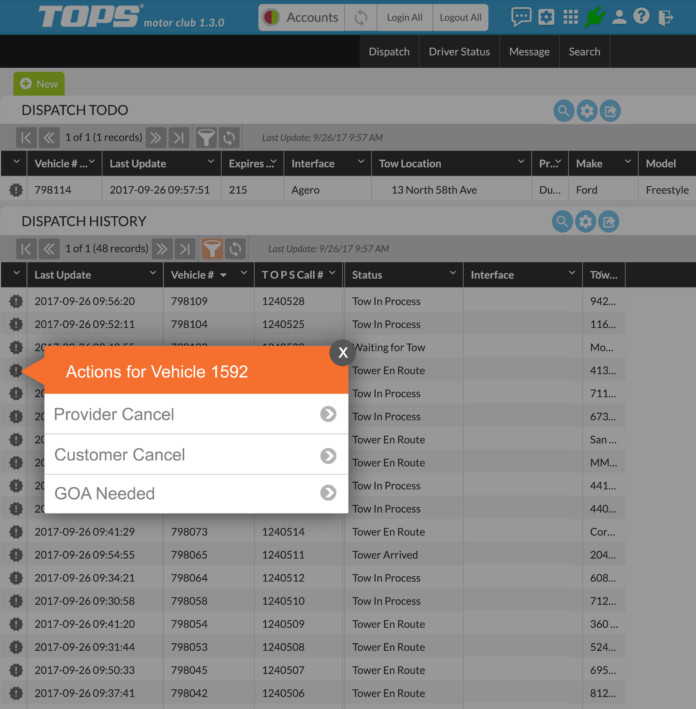

Many motor clubs are increasingly using digital dispatch systems to send calls to their tower base in an effort to drive costs and arrival times down. Many clubs have made it a requirement to continue to do business with them. Early on these digital interfaces were proprietary to the motor club and sometimes required club-specific systems. Many dispatch systems now have a dedicated motor club interface for receiving and responding to motor club tow requests which merge clubs into a single, easy to understand system. This allows your staff to see and respond to motor club requests much quicker and easier, and simplifies the entire process.

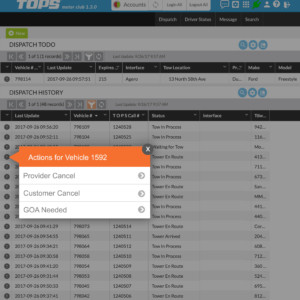

TOPS Motor Club is the TOPS digital dispatch interface to receive and respond to digital platform motor club calls. TOPS Motor club receives digital tow requests from ADS, Agero, Allstate, GEICO, NSD, Quest, Road America, Tesla, USAC and FleetNet. As tow and service requests are received and negotiated, calls are pushed directly into the TOPS dispatch system. This offers an efficient transfer of information into TOPS for dispatch to the best driver / truck resource. Updates are shared back to the respective motor club, offering a full two-way integration with each motor club. Using integrated tools like TOPS Motor Club can help your company receive additional work and increase your call volume.

Mobile Applications

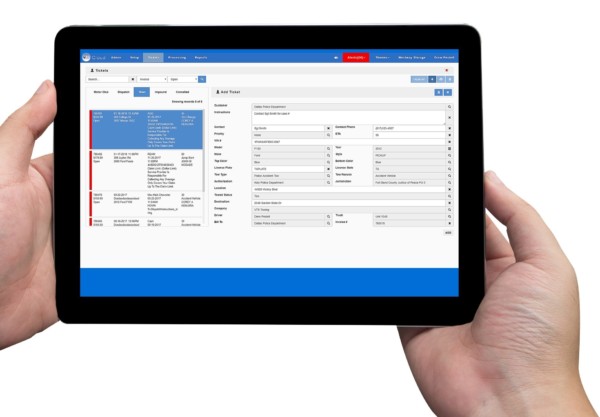

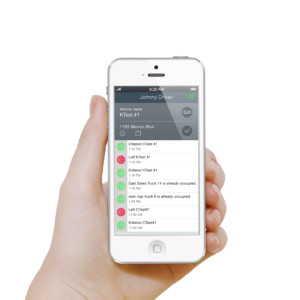

Mobile applications have become a critical tool for businesses on the go. Mobile applications enable workers in the field to quickly and easily access and update data and to support their job functions. As law enforcement and motor clubs increasingly require real-time driver status updates and ETAs, mobile applications are the only way to realistically provide these.

Mobile applications have become a critical tool for businesses on the go. Mobile applications enable workers in the field to quickly and easily access and update data and to support their job functions. As law enforcement and motor clubs increasingly require real-time driver status updates and ETAs, mobile applications are the only way to realistically provide these.

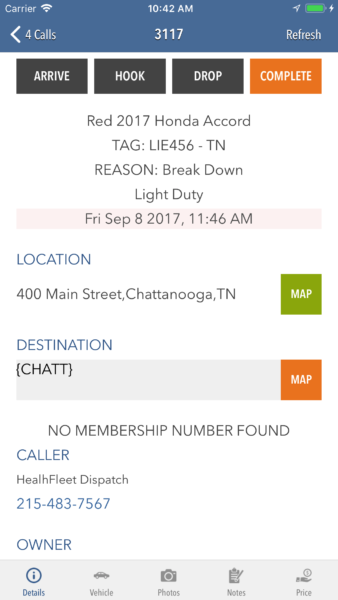

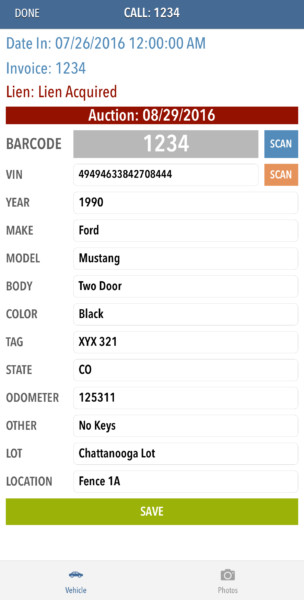

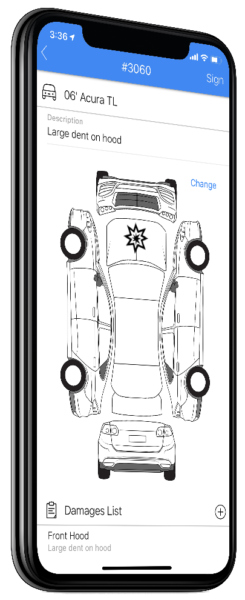

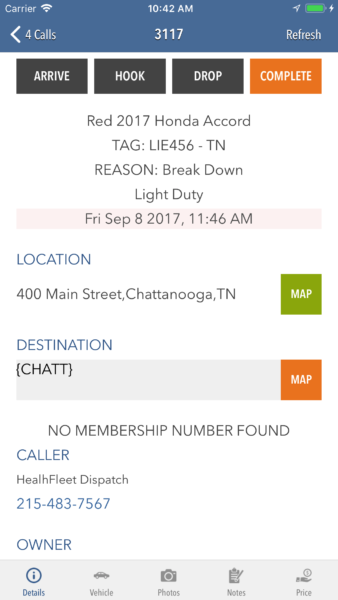

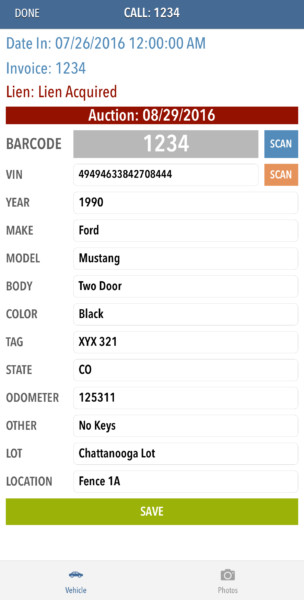

Using effective mobile applications, drivers and supervisors can update call status times, navigate to pickup and drop-off locations, upload and store vehicle- and incident-related information and photographs, create and dispatch new calls and email call receipts to customers directly from their mobile device in the field. Impound-lot personnel can enter and update vehicle information, do physical inventories and inspections, take photographs, and scan barcodes for ease of managing lot inventory. When these systems are interconnected with municipality systems, the updating and sharing of data provides transparency that cannot be obtained any other way.

The TOPS® suite of mobile applications includes apps to aid field and inventory operations. All mobile apps are designed for iOS and Android mobile phones and tablets. TOPS Driver allows the driver to receive, update and even create calls on the fly. The TOPS Inventory application is designed for the impound-lot staff to take physical inventories, search for vehicle information and update records as needed. The TOPS Xtra app ties completely customizable functionality to our standard TOPS Driver and TOPS Inventory applications. An example is to add a customized paperless tow sheet to TOPS Driver or a customized impound inspection process to TOPS Inventory.

The TOPS® suite of mobile applications includes apps to aid field and inventory operations. All mobile apps are designed for iOS and Android mobile phones and tablets. TOPS Driver allows the driver to receive, update and even create calls on the fly. The TOPS Inventory application is designed for the impound-lot staff to take physical inventories, search for vehicle information and update records as needed. The TOPS Xtra app ties completely customizable functionality to our standard TOPS Driver and TOPS Inventory applications. An example is to add a customized paperless tow sheet to TOPS Driver or a customized impound inspection process to TOPS Inventory.

Web-based Applications

Web-based applications have opened new doors for towing businesses to increase cash sales. Web-based applications enable the person on the street to search out a local tower and request a tow, by simply clicking on a link on a web page that the tower provides. By clicking a link, the system can determine their location and create a tow request, which can be directed to the closest available driver via the GPS location of the trucks. This provides the person on the side of the road with unprecedented access to services that they have never had before along with the peace of mind knowing that help is on the way.

GPS Interface

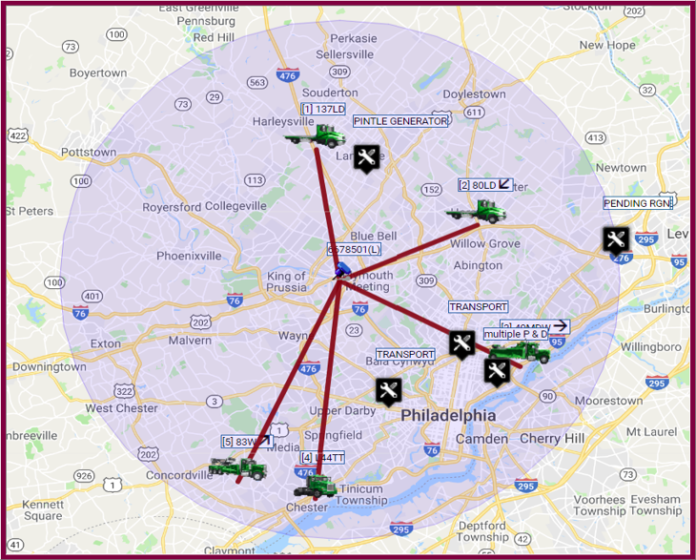

The most valuable physical asset a towing company has is its fleet of trucks and equipment. Each truck constitutes a significant financial investment, as well as being a rolling advertisement for the company at all times while on the road. Many companies have chosen to protect that investment by installing GPS devices in their trucks. These devices can be hard-wired, or in some cases can be plugged into the vehicle’s OBDII port as a ‘plug-n-play’ solution. These devices can often be purchased for relatively small investments.

The GPS device is only half of the story. The other half is the software interface designed around the device. What good is knowing the lat/long of a truck if you don’t know where that is on a map? A good GPS system relies on software that is engineered to support the user and the business that they are in. The BudgetGPS system is a vehicle and fleet tracking solution that can be used by any industry, but is specifically tuned to support the towing industry. BudgetGPS integrates with the TOPScma system and the TOPS software to offer a true visual dispatching tool, where users are able to view current vehicle locations, unassigned pickup and drop-off locations – all on the same map. Icons are color coded allowing for a visual picture of calls in-process and those that are clearing. Knowing this information can save time, and time is money. Additionally, users are able to monitor ETA’s based on mapping calculations of drive time between the truck and pickup locations. The BudgetGPS system also allows for dispatching the closest truck to the breakdown, by using the ETA of each available truck and its proximity to the incident location. This feature is becoming the option of choice for law enforcement agencies, as it has shown time and time again to provide the lowest ETAs, and the streets are cleared the quickest.

BudgetGPS delivers a full set of features for a single low price. These include things like Live Map with 20-second vehicle updates and live Google traffic for both the map and satellite views, a historical breadcrumb view with 6 months of history, Alerts and Monitoring for PTO, GeoFence, Ignition, and Speeding. Reports include Driver Distance, State Mileage, Stops, Speeding and more.

About towXchange

TXI Systems, Inc. dba towXchange markets and sells towing management products under the brand name of TOPS®. The TOPS® suite of products is deployed to private tow operators, municipalities and law enforcement. TOPS® software tools support towing dispatch, freeway service patrol, impound lot management, private property towing and more with efficiency, transparency, and accountability in mind. BudgetGPS fleet tracking is also marketed to the towing industry and offers a full-service fleet tracking tool with includes a visual dispatching integration with TOPS®. Let TXI Systems customize a solution for you today!

For more information or to schedule a demonstration, please call 866-800-8677 Opt 2 or visit our websites – TOPS® – www.towxchange.net BudgetGPS – www.budgetgps.com.

TOPS® is a Registered Trademark of TXI Systems, Inc.

Responding to State Specific Requirements

Responding to State Specific Requirements ADD is in the unique position of being the only NMVTIS history provider that is also a consolidator of JSI (junk, salvage and insurance) data for industry members, making both accessing a history and reporting data as easy as 1, 2, 3. For tow/wrecker operators who need to report junk or salvage vehicles to NMVTIS, ADD provides a solution from the same web-based account. Any entity that deals in more than five junk and salvage vehicles per year must provide specific vehicle information to the national database on at least a monthly basis. NMVTIS reporting applies to any vehicle a company parts out or crushes, or any vehicle for which a salvage certificate, a certificate of destruction or similar document is obtained. If a business has the right to sell or re-title, rebuild, restore or crush the vehicle, and it is a junk or salvage vehicle under the federal definition, it must be reported to NMVTIS.

ADD is in the unique position of being the only NMVTIS history provider that is also a consolidator of JSI (junk, salvage and insurance) data for industry members, making both accessing a history and reporting data as easy as 1, 2, 3. For tow/wrecker operators who need to report junk or salvage vehicles to NMVTIS, ADD provides a solution from the same web-based account. Any entity that deals in more than five junk and salvage vehicles per year must provide specific vehicle information to the national database on at least a monthly basis. NMVTIS reporting applies to any vehicle a company parts out or crushes, or any vehicle for which a salvage certificate, a certificate of destruction or similar document is obtained. If a business has the right to sell or re-title, rebuild, restore or crush the vehicle, and it is a junk or salvage vehicle under the federal definition, it must be reported to NMVTIS.

Depending on where in North America you live and operate your towing and vehicle storage business, spring has either arrived or is just around the corner. Spring is generally a happy time, where nature begins its renewal cycle, encouraged by nature’s all-consuming driving force. Many of you will be thinking of ways in which to improve the efficiency of your business and its competitive advantage.

Depending on where in North America you live and operate your towing and vehicle storage business, spring has either arrived or is just around the corner. Spring is generally a happy time, where nature begins its renewal cycle, encouraged by nature’s all-consuming driving force. Many of you will be thinking of ways in which to improve the efficiency of your business and its competitive advantage. Perception is not always a shiny reality. A shiny new company tow truck may project an image of success. However, long-term business and financial success does not begin, nor end with shiny new trucks, as they often carry a financial burden. Focus on setting standards. it does not have to be new, older tow trucks if clean, and well maintained, often project a trusted conservative image. If operating multiple trucks, set a goal of having them all the same color, plus a company branding/logo and a door wrap will increase public awareness. This, along with polite operators wearing clean uniforms, present an image of professionalism and efficiency.

Perception is not always a shiny reality. A shiny new company tow truck may project an image of success. However, long-term business and financial success does not begin, nor end with shiny new trucks, as they often carry a financial burden. Focus on setting standards. it does not have to be new, older tow trucks if clean, and well maintained, often project a trusted conservative image. If operating multiple trucks, set a goal of having them all the same color, plus a company branding/logo and a door wrap will increase public awareness. This, along with polite operators wearing clean uniforms, present an image of professionalism and efficiency.

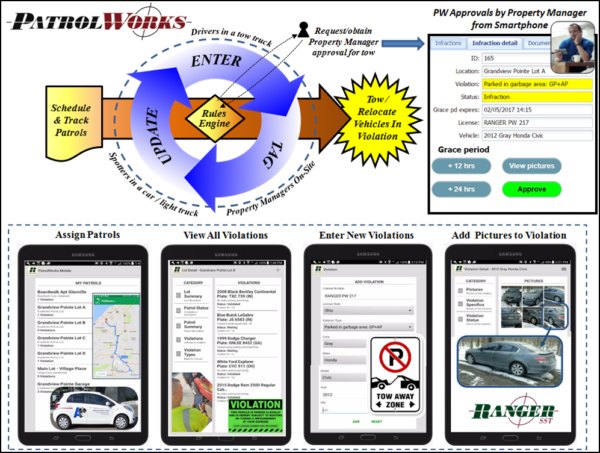

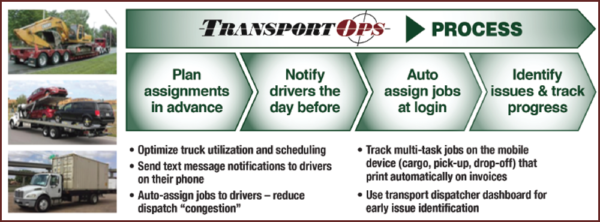

Scheduling for Transport and Heavy Hauling

Scheduling for Transport and Heavy Hauling Services Agreement

Services Agreement

These features are designed to keep your information secure, while boosting your company’s productivity. We’re transparent about our latest updates and give our customers all the information they need to understand each new feature. Visit our Help Desk for all the latest tutorials and information!

These features are designed to keep your information secure, while boosting your company’s productivity. We’re transparent about our latest updates and give our customers all the information they need to understand each new feature. Visit our Help Desk for all the latest tutorials and information! The Beacon Blog is Live!

The Beacon Blog is Live!

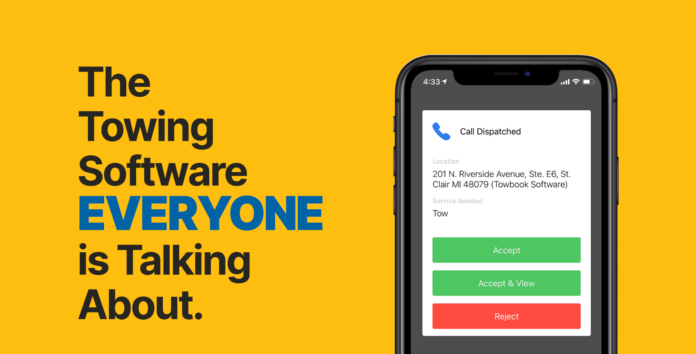

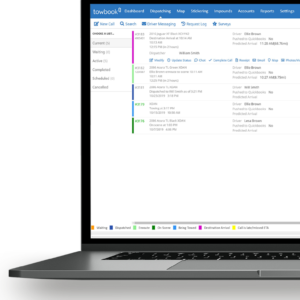

As the use of technology continues to rise in the towing and roadside industry, so do consumer expectations. With the ability to use advanced technology at your fingertips, your customer expects to be informed and cared for every step of the way. Using Towbook facilitates this communication by doing the work for you!

As the use of technology continues to rise in the towing and roadside industry, so do consumer expectations. With the ability to use advanced technology at your fingertips, your customer expects to be informed and cared for every step of the way. Using Towbook facilitates this communication by doing the work for you! Managers and dispatchers can communicate with drivers easily. Drivers can accept calls with all the details needed in order to do their job efficiently and update the status of the job from start to finish. You will also be able to chat with your drivers via their mobile applications or send them a text message to make them aware of last-minute changes (chat logs are always saved to the call for future reference).

Managers and dispatchers can communicate with drivers easily. Drivers can accept calls with all the details needed in order to do their job efficiently and update the status of the job from start to finish. You will also be able to chat with your drivers via their mobile applications or send them a text message to make them aware of last-minute changes (chat logs are always saved to the call for future reference). With Roadside.io, you have the option of sharing information with customers while the service is in progress, helping customers understand what’s happening with their service without having to call you for an update. You also have the option of sending the customer a satisfaction survey once the job is complete. You can choose to push these surveys to your website, and you can also direct them to your social media outlets where they can complete a review about the service they received.

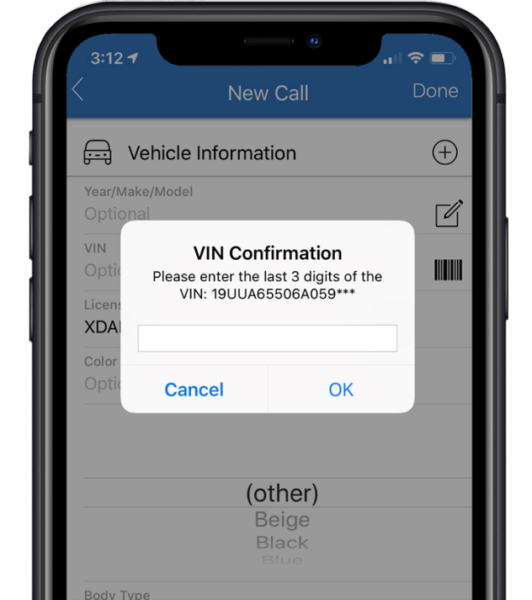

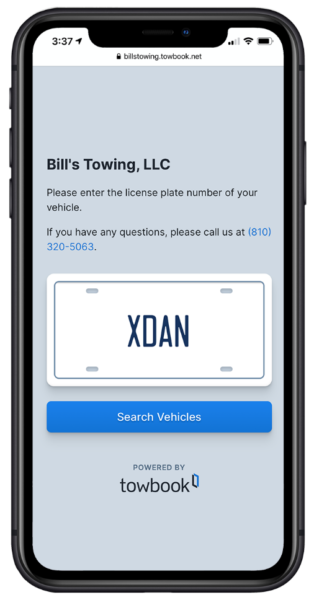

With Roadside.io, you have the option of sharing information with customers while the service is in progress, helping customers understand what’s happening with their service without having to call you for an update. You also have the option of sending the customer a satisfaction survey once the job is complete. You can choose to push these surveys to your website, and you can also direct them to your social media outlets where they can complete a review about the service they received. No VIN – no problem! Towbook’s plate-to-VIN feature saves time and eliminates mistakes. Simply enter the plate number and the state in which the vehicle is licensed, and Towbook will return the full VIN with the make, model, and year of the vehicle. You’ll also have the option of using our VIN scanner, which will populate the VIN in the call just by scanning the vehicle’s barcode.

No VIN – no problem! Towbook’s plate-to-VIN feature saves time and eliminates mistakes. Simply enter the plate number and the state in which the vehicle is licensed, and Towbook will return the full VIN with the make, model, and year of the vehicle. You’ll also have the option of using our VIN scanner, which will populate the VIN in the call just by scanning the vehicle’s barcode. release your current impounded/stored vehicles on your lot right from the mobile application. You’ll even be able to send the impound invoice via text or e-mail.

release your current impounded/stored vehicles on your lot right from the mobile application. You’ll even be able to send the impound invoice via text or e-mail.

The days when towing companies could run operations with a pad a pencil are a thing of the past. The demands of the industry are changing rapidly, and without adequate computer systems to manage those, companies can and will fall behind. With digital dispatching and complex reporting requirements coming from all sides, towing companies need sophisticated systems to handle these increasing demands to compete in this ever-changing landscape.

The days when towing companies could run operations with a pad a pencil are a thing of the past. The demands of the industry are changing rapidly, and without adequate computer systems to manage those, companies can and will fall behind. With digital dispatching and complex reporting requirements coming from all sides, towing companies need sophisticated systems to handle these increasing demands to compete in this ever-changing landscape. Municipality and Law Enforcement Towing

Municipality and Law Enforcement Towing Mobile applications have become a critical tool for businesses on the go. Mobile applications enable workers in the field to quickly and easily access and update data and to support their job functions. As law enforcement and motor clubs increasingly require real-time driver status updates and ETAs, mobile applications are the only way to realistically provide these.

Mobile applications have become a critical tool for businesses on the go. Mobile applications enable workers in the field to quickly and easily access and update data and to support their job functions. As law enforcement and motor clubs increasingly require real-time driver status updates and ETAs, mobile applications are the only way to realistically provide these. The TOPS® suite of mobile applications includes apps to aid field and inventory operations. All mobile apps are designed for iOS and Android mobile phones and tablets. TOPS Driver allows the driver to receive, update and even create calls on the fly. The TOPS Inventory application is designed for the impound-lot staff to take physical inventories, search for vehicle information and update records as needed. The TOPS Xtra app ties completely customizable functionality to our standard TOPS Driver and TOPS Inventory applications. An example is to add a customized paperless tow sheet to TOPS Driver or a customized impound inspection process to TOPS Inventory.

The TOPS® suite of mobile applications includes apps to aid field and inventory operations. All mobile apps are designed for iOS and Android mobile phones and tablets. TOPS Driver allows the driver to receive, update and even create calls on the fly. The TOPS Inventory application is designed for the impound-lot staff to take physical inventories, search for vehicle information and update records as needed. The TOPS Xtra app ties completely customizable functionality to our standard TOPS Driver and TOPS Inventory applications. An example is to add a customized paperless tow sheet to TOPS Driver or a customized impound inspection process to TOPS Inventory.

Safety begins with design, so Custom Built first looks where the danger areas are for the towers. They then layout the truck around two things: they place the towing and recovery tools on the left side of the truck and then place the controls on the right side where the operator will be standing away from traffic. Their goal is balance between keeping the tower safe and keeping the job work efficient. Another way they enhance safety by design is by providing extra lighting on the truck and reflectives on both the truck and toolboxes which signal on-coming drivers to move over without being too over-the-top which would distract drivers causing them to drift toward the trucks.

Safety begins with design, so Custom Built first looks where the danger areas are for the towers. They then layout the truck around two things: they place the towing and recovery tools on the left side of the truck and then place the controls on the right side where the operator will be standing away from traffic. Their goal is balance between keeping the tower safe and keeping the job work efficient. Another way they enhance safety by design is by providing extra lighting on the truck and reflectives on both the truck and toolboxes which signal on-coming drivers to move over without being too over-the-top which would distract drivers causing them to drift toward the trucks.

As I mentioned in last month’s article, I talked about finding tow truck drivers for the future. We all know our industry is short of drivers, and it’s time to fix the problem. I met with several tow company owners last week, and we talked at length about how to find drivers.

As I mentioned in last month’s article, I talked about finding tow truck drivers for the future. We all know our industry is short of drivers, and it’s time to fix the problem. I met with several tow company owners last week, and we talked at length about how to find drivers.

For almost three decades, WreckMaster has been working towards creating a safer, more efficient and better compensated towing and recovery industry. Through hands-on training, mentorship and certification, we have reached over 40,000 towers since 1991. Today, we host hundreds of classes and train thousands of students every single year.

For almost three decades, WreckMaster has been working towards creating a safer, more efficient and better compensated towing and recovery industry. Through hands-on training, mentorship and certification, we have reached over 40,000 towers since 1991. Today, we host hundreds of classes and train thousands of students every single year.

It’s time to be honest with yourself. Are you or your lead drivers allergic to training? Are you afraid you’ll learn something or attend a course, class, or school where someone knows more than you on a given subject? I’m not trying to call you out or call you a “chicken” or a “coward.” I’m trying to get you to see past a common feeling in our industry in order to protect yourself, your business, and your employees.

It’s time to be honest with yourself. Are you or your lead drivers allergic to training? Are you afraid you’ll learn something or attend a course, class, or school where someone knows more than you on a given subject? I’m not trying to call you out or call you a “chicken” or a “coward.” I’m trying to get you to see past a common feeling in our industry in order to protect yourself, your business, and your employees.

Cleveland (Liberty County), Texas – Although rain wasn’t in the forecast, it is seemingly appropriate that a light rain began falling just before the procession began and subsided just afterwards. Liberty County Sheriff’s Deputy, Richard Whitten, was laid to rest today, and the attendance and participation in his funeral and procession was nothing short of staggering; it was a truly humbling experience to witness.

Cleveland (Liberty County), Texas – Although rain wasn’t in the forecast, it is seemingly appropriate that a light rain began falling just before the procession began and subsided just afterwards. Liberty County Sheriff’s Deputy, Richard Whitten, was laid to rest today, and the attendance and participation in his funeral and procession was nothing short of staggering; it was a truly humbling experience to witness. Deputy Whitten was shot in the neck last year by a murder suspect during an incident in Cleveland, a small town northwest of Houston. He was recovering well in the rehabilitation process according to medical personnel, but then suffered a heart attack during physical therapy last week. Deputy Whitten was just named “Officer of the Year” by the Houston Area 100 Club. He left behind his wife and two children.

Deputy Whitten was shot in the neck last year by a murder suspect during an incident in Cleveland, a small town northwest of Houston. He was recovering well in the rehabilitation process according to medical personnel, but then suffered a heart attack during physical therapy last week. Deputy Whitten was just named “Officer of the Year” by the Houston Area 100 Club. He left behind his wife and two children.

F

F After all, it is well established that drivers that know they are being monitored by such systems are less likely to make unnecessary detours or stops for personal reasons, may avoid spending unnecessary time at job sites, and/or avoid idling the engine while filling out paperwork in the vehicle.

After all, it is well established that drivers that know they are being monitored by such systems are less likely to make unnecessary detours or stops for personal reasons, may avoid spending unnecessary time at job sites, and/or avoid idling the engine while filling out paperwork in the vehicle. Once drivers and the work crew know they are accountable for their actions, it is amazing how much more they will accomplish.

Once drivers and the work crew know they are accountable for their actions, it is amazing how much more they will accomplish.