MatJack is an industry-leading custom manufacturer of air lifting bags and cushions. Throughout our 40 years in business, we’ve established a reputation for quality products and superior services. MatJack offers low pressure, medium pressure, & high-pressure lift bags, jumbo recovery cushions, catch bags, headsets, and helmets and much more. Customers across the globe know they can rely on us to meet their air lifting needs.

LOW PRESSURE AIR LIFTING CUSHIONS

MatJack low pressure lifting cushions require only 1-3”/ 25-75mm clearance and can lift tons of weight with as little as 2psi/ .14bar.

MatJack low pressure lifting cushions require only 1-3”/ 25-75mm clearance and can lift tons of weight with as little as 2psi/ .14bar.

MatJack low pressure lifting cushions work best in cantilever or “hinged” style lifts but can also be used for vertical lifting if rigged correctly so lateral movement of the weight being lifted is restricted. MatJack low pressure cushions work on volume rather than pressure to create the lift, working from8-10 psi/.5-.7 bar depending on the model.

MatJack low pressure cushions, unlike high pressure air lifting bags which lose capacity as they inflate, lift the weight they are rated for the full lift stroke of the cushion.

MatJack low pressure cushions are made with Hypalon and Neoprene for unmatched durability and strength, which is why they are the number one choice for low pressure equipment among rescue squads, all branches of the U.S. military and civil defense agencies worldwide.

MatJack low pressure cushions not only come in 12 standard sizes, but they can also be made any size to meet a customer’s individual needs.

MatJack low pressure cushions have a 5-year warranty, but with normal care and maintenance, they should work well over 20 years trouble free.

MEDIUM PRESSURE LIFTING CUSHIONS

MatJack Medium Pressure Lifting Cushions require only 1-3 inches clearance for insertion with the main advantage over low pressure cushions being they provide heavier tonnage lifting capacities for similar size low pressure cushions while requiring less work area and taking up less storage space. MatJack Medium Pressure Lifting Cushions work best in cantilever or “hinged” style lifts but can also be used for vertical lifting if rigged correctly so lateral movement of the weight being lifted is restricted.

MatJack Medium Pressure Lifting Cushions require only 1-3 inches clearance for insertion with the main advantage over low pressure cushions being they provide heavier tonnage lifting capacities for similar size low pressure cushions while requiring less work area and taking up less storage space. MatJack Medium Pressure Lifting Cushions work best in cantilever or “hinged” style lifts but can also be used for vertical lifting if rigged correctly so lateral movement of the weight being lifted is restricted.

MatJack medium pressure cushions work on volume rather than pressure to create the lift, working at 15 psi / 1 bar of pressure and can lift as much as 35,000 lbs./ 15,900 kgs. up to 40”/ 1000mm, which is the major difference between low and medium pressure cushions. Both provide more height than high pressure for accessibility with the medium pressure lifting providing more weight capacity than low pressure due to the higher operating pressure.

MatJack medium pressure cushions, unlike the high-pressure air lifting bags, lift the weight they are rated for the full height of the cushion.

MatJack medium pressure cushions are made with Kevlar/ Aramid fiber reinforced Neoprene for unmatched durability and strength, which is why they are the number one choice for medium pressure equipment among rescue squads, civil defense and military agencies worldwide.

HIGH-PRESSURE AIR LIFTING BAGS AT MatJack

Our high-pressure air lifting bags are designed to lift and move up to 86 tons at a touch of a button with an initial clearance of only 1 inch. They are made with four full layers of aramid fiber per side. This unique construction makes them a strong but lightweight lifting solution for some of the most rugged, demanding, and heavy-duty applications. They can be used in adverse environments, such as sharp gravel, muddy banks, wet grass, and icy ground.

Our high-pressure air lifting bags are designed to lift and move up to 86 tons at a touch of a button with an initial clearance of only 1 inch. They are made with four full layers of aramid fiber per side. This unique construction makes them a strong but lightweight lifting solution for some of the most rugged, demanding, and heavy-duty applications. They can be used in adverse environments, such as sharp gravel, muddy banks, wet grass, and icy ground.

Key features include:

• Simple handheld controls. The controls can have pushbutton, Deadman, or joystick controllers that allow for independent, single-bag or simultaneous, multi-bag operation. The pushbutton control variations have one button for inflation and one button for deflation.

• 20-foot high-pressure hose. The long hose ensures operators are not under or near the load as it is lifted or moved. It is color-coded to eliminate confusion in situations where more than one bag is operated at the same time.

• Carry handles or tabs/eyelets. These elements facilitate lifting and fixture attachment.

• Raised, conical, and interlocking surface. They are covered with five layers of neoprene rubber for an outer surface that grips load and provides traction.

• Distinct tonnage rating marking. Each bag is marked with a bullseye containing the tonnage rating for easy centering under the load and identification in fast-paced, low-visibility situations.

MatJack high-pressure air lifting bags are 100% made in the USA and ISO 9001:2008 and CE certified. They also come with a five-year unconditional warranty.

JUMBO TURBO SAFELIFT RECOVERY CUSHIONS

Jumbo Turbo Safelift cushions are the first choice of Recovery personnel worldwide when it comes to up righting overturned tractor/trailers, aircraft recovery or any recovery which requires the best quality, heaviest duty air cushions and equipment available.

Jumbo Turbo Safelift cushions are the first choice of Recovery personnel worldwide when it comes to up righting overturned tractor/trailers, aircraft recovery or any recovery which requires the best quality, heaviest duty air cushions and equipment available.

Jumbo’s come in both sloped and flat top design. Jumbos are the only slope topped bag, with its patented design to exclusively follow a lift all the way up without ever losing contact with ground or the load, MatJack Jumbo bags are the only cushions manufactured which can make this claim and prove it! MatJack Jumbo flat top cushions are primarily used for aircraft recovery.

Jumbo Turbo cushions come in complete sets or individually. Everything is included in each set to get you up and working within a matter of minutes. From our Support set, designed to replace worn out existing sets with still functional (1 or 2) large cushions which can be converted to Turbos, up to our Comprehensive Set, with 8 Jumbos and 3 starters, you get all the unsurpassed quality, service and training you have come to expect from MatJack.

LANDING SAFELIFT BAGS

Since 2005, MatJack Landing Bags have provided users the ability to do recovery uprights on tractor trailers, heavy tracked equipment, box trucks, overturned mobile homes, etc.… without the use of a “catch” vehicle. Landing bags work due to a constant airflow and require it to stay inflated. Landing bags are placed under a load with the intention of not allowing the load to gain speed during up righting operations and descent of the load past fulcrum point. Landing bags lift, support and control vehicles as they come over while allowing the air to escape through 3 ported openings in each cushion increasing control of the vehicle and rate of descent. This is critically important to avoid further damage to equipment. Rapid, uncontrolled descent of any equipment is dangerous and should be avoided to prevent potential injury or loss of life!

Since 2005, MatJack Landing Bags have provided users the ability to do recovery uprights on tractor trailers, heavy tracked equipment, box trucks, overturned mobile homes, etc.… without the use of a “catch” vehicle. Landing bags work due to a constant airflow and require it to stay inflated. Landing bags are placed under a load with the intention of not allowing the load to gain speed during up righting operations and descent of the load past fulcrum point. Landing bags lift, support and control vehicles as they come over while allowing the air to escape through 3 ported openings in each cushion increasing control of the vehicle and rate of descent. This is critically important to avoid further damage to equipment. Rapid, uncontrolled descent of any equipment is dangerous and should be avoided to prevent potential injury or loss of life!

MatJack Landing Bags are typically used under wheels of vehicles to control descent but have also been used under frame sections to catch box trucks and mobile homes and even track drives on cranes.

Single lane uprights are now accomplished in a much easier fashion with less set up and quicker dismantle time for those “quick clear incident” situations. Any upright recovery is now quicker, safer and more professionally done when using MatJack Landing Bags!

Landing Bags come in complete sets or individually. Everything is included in each set to get you up and working within a matter of minutes.

Landing Bags are made of a special material designed to resist tearing but allow quick repair if damaged in the field. The large Camlock fittings provide for quick assembly and disassembly of the system.

All MatJack Landing Bag systems will provide you with years of trouble-free use and come with the same outstanding warranty, service, training and care you have come to expect from MatJack.

MatJack also offers headsets and a variety of helmets. MatJack offers easy to use headsets providing hearing protection and a convenient way for your team to communicate in noisy environments. Voice activated both FULL DUPLEX and BASIC. PMI Advantage Helmets offer classic styling, maximum comfort and minimum impact. PMI Advantage Helmets have industrial Kevlar head protection and plenty of detail-oriented comfort. Fully adjustable ratchet headband and straps make this a helmet for almost any size head. Meets NFPA 1951 as a Utility Technical Rescue Protective Helmet Standard.

When it comes to your next recovery MatJack has you covered! For more information visit us at www.MatJack.com.

Shannon Bryant Wrecker is offering a complete kit for releasing any tractor and or trailer with air brakes. Their deluxe kit comes with everything to you need to get the job done! Designed by Towers for Tow Professionals!

Shannon Bryant Wrecker is offering a complete kit for releasing any tractor and or trailer with air brakes. Their deluxe kit comes with everything to you need to get the job done! Designed by Towers for Tow Professionals!

The International Towing & Recovery Hall of Fame and Museum has announced it will induct 10 new members into its Hall of Fame this fall. The inductees hail from the United States, Australia, France, and Japan, making it one of the most diverse Hall of Fame classes ever.

The International Towing & Recovery Hall of Fame and Museum has announced it will induct 10 new members into its Hall of Fame this fall. The inductees hail from the United States, Australia, France, and Japan, making it one of the most diverse Hall of Fame classes ever.

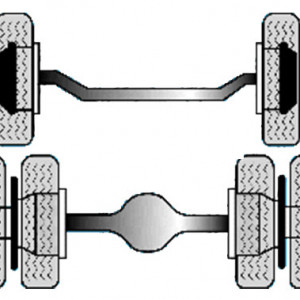

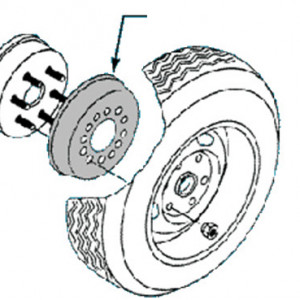

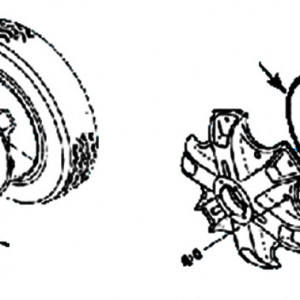

Rotary bearing for instant mobility

Rotary bearing for instant mobility

I guess for me, the most important thing I would change would be to insist on more family time.

I guess for me, the most important thing I would change would be to insist on more family time.

Our high-pressure air lifting bags are designed to lift and move up to 86 tons at a touch of a button with an initial clearance of only 1 inch. They are made with four full layers of aramid fiber per side. This unique construction makes them a strong but lightweight lifting solution for some of the most rugged, demanding, and heavy-duty applications. They can be used in adverse environments, such as sharp gravel, muddy banks, wet grass, and icy ground.

Our high-pressure air lifting bags are designed to lift and move up to 86 tons at a touch of a button with an initial clearance of only 1 inch. They are made with four full layers of aramid fiber per side. This unique construction makes them a strong but lightweight lifting solution for some of the most rugged, demanding, and heavy-duty applications. They can be used in adverse environments, such as sharp gravel, muddy banks, wet grass, and icy ground.

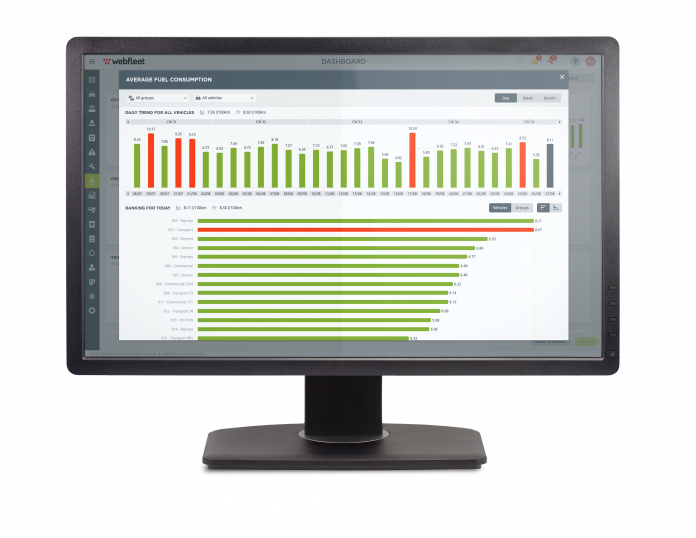

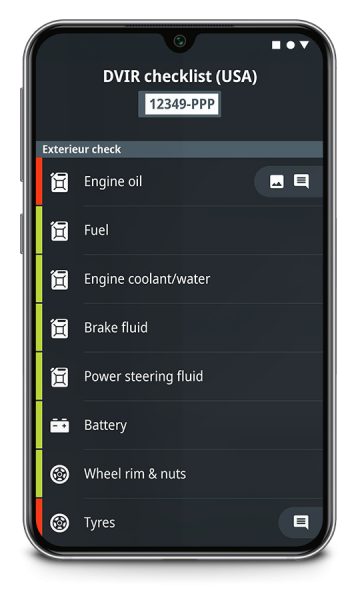

WEBFLEET offers a range of hardware, software, products, and solutions that can help you decrease your costs. By choosing the right combination for your fleet, you can ensure that, at every step of your journey, you are efficiently bringing down your overall spend.

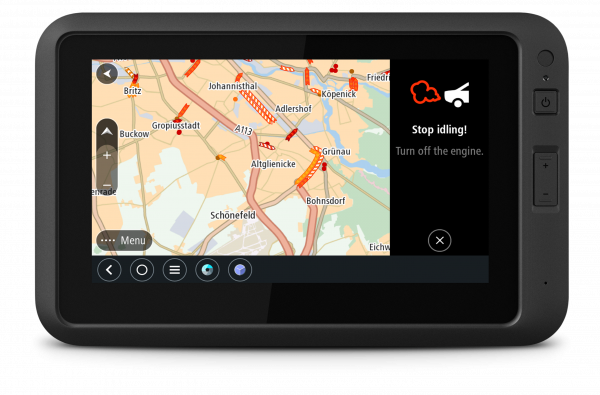

WEBFLEET offers a range of hardware, software, products, and solutions that can help you decrease your costs. By choosing the right combination for your fleet, you can ensure that, at every step of your journey, you are efficiently bringing down your overall spend. Even the best driver can use more fuel than is necessary if they are on the wrong route. The professional truck navigation of the PRO Driver Terminal series from Webfleet shows truck drivers the most suitable routes for them, so there’s less chance of driving unnecessary miles. It also offers access to up-to-date traffic information to keep you out of traffic jams where idling can increase fuel consumption.

Even the best driver can use more fuel than is necessary if they are on the wrong route. The professional truck navigation of the PRO Driver Terminal series from Webfleet shows truck drivers the most suitable routes for them, so there’s less chance of driving unnecessary miles. It also offers access to up-to-date traffic information to keep you out of traffic jams where idling can increase fuel consumption.